What Is a Lathe Spindle Bore? (Basic Definition)

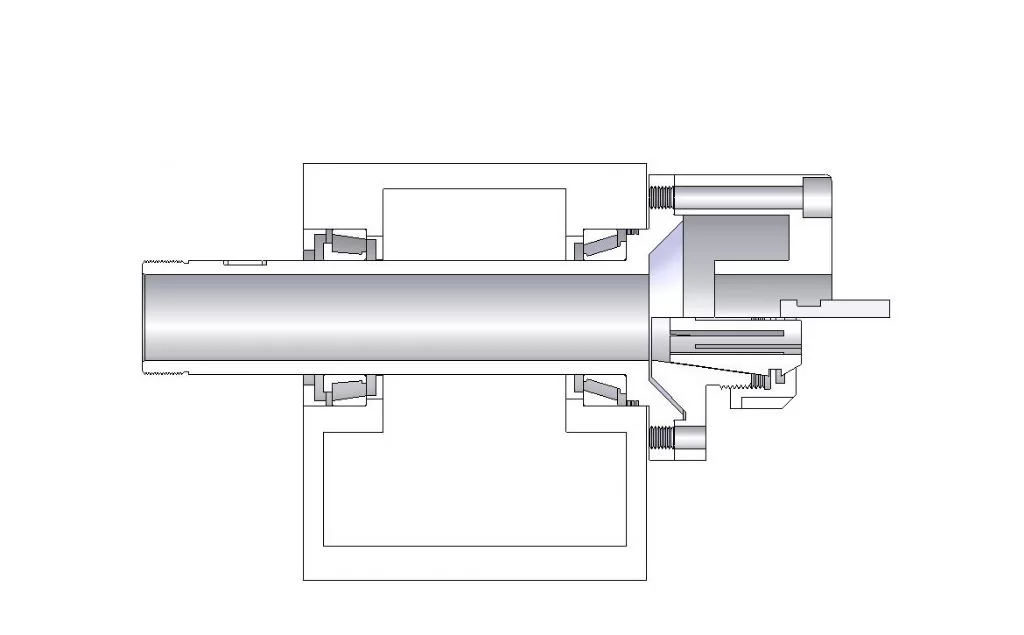

A lathe spindle bore refers to the hollow opening that runs through the center of the lathe’s spindle. It allows bar stock, tubes, or long materials to pass through the spindle for continuous or extended machining. In simple terms, the spindle bore determines the maximum diameter of material that can feed directly through the spindle, making it one of the most important specifications when selecting a CNC or conventional lathe.

Unlike spindle diameter—which refers to the external size of the spindle housing—the spindle bore focuses on internal capacity. A larger bore enables a lathe to process thicker or longer workpieces, supports automatic bar feeding, and increases flexibility across various turning applications. Because of this, spindle bore size directly influences the types of jobs a lathe can handle and its overall machining efficiency.

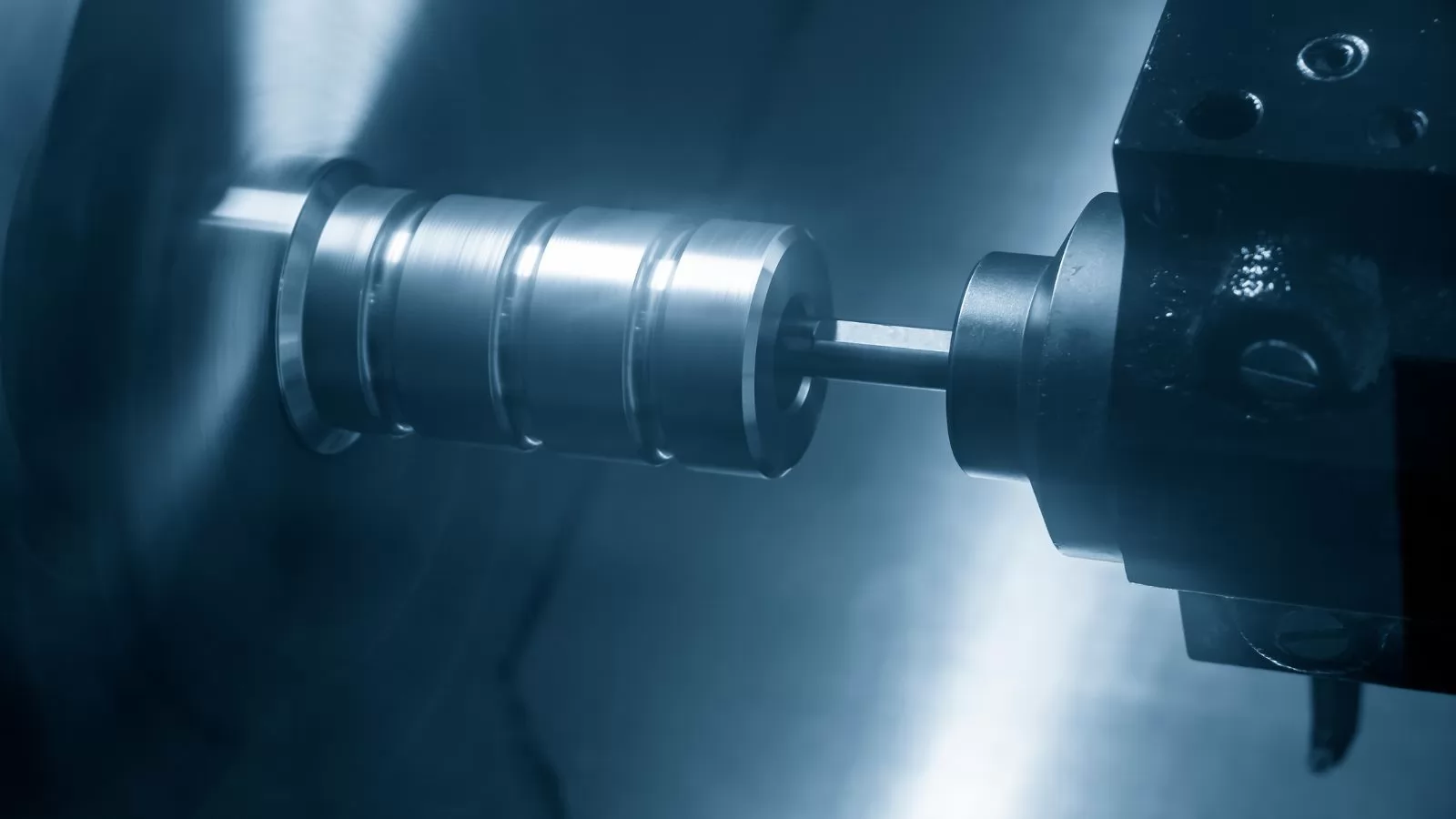

Why Spindle Bore Size Matters in CNC Turning

The spindle bore size plays a crucial role in determining a lathe’s machining capability. For CNC turning operations, the bore size directly influences the maximum bar diameter that can be fed through the spindle, which affects the type and scale of workpieces the machine can handle. A properly selected spindle bore helps improve production efficiency and reduces the need for secondary setups.

A larger spindle bore allows operators to work with thick-walled tubes, long shafts, and oilfield pipes, making it essential for industries such as energy, automotive, and hydraulic equipment manufacturing. On the other hand, smaller spindle bores provide higher rigidity and are ideal for precision components. Understanding this balance enables buyers to choose a lathe that meets both performance and cost-efficiency requirements.

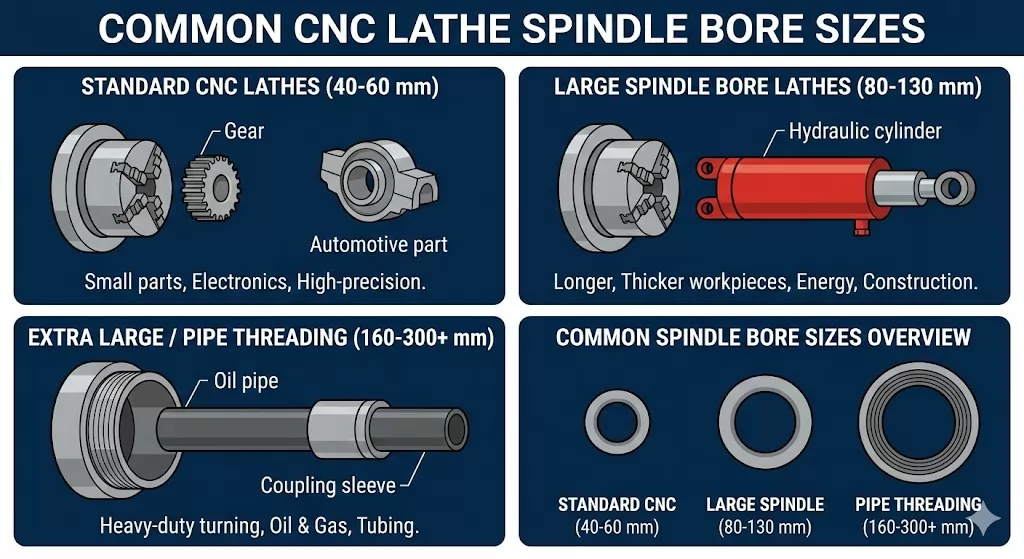

Common Spindle Bore Sizes in CNC Lathes

CNC lathes are available with a wide range of spindle bore sizes to accommodate different machining needs. Manufacturers typically categorize lathes based on bore diameter, as this specification directly corresponds to the machine’s intended application. Smaller bores are used for precision components, while larger bores serve industries that require the machining of pipes, tubes, or oversized bar stock.

Standard CNC Lathes

Standard CNC lathes usually feature spindle bores ranging from 40 mm to 60 mm. This size range is suitable for general-purpose machining, small automotive parts, metal components, electronics, and mold-related applications. These machines offer strong rigidity and stable performance, making them ideal for high-precision work.

Large Spindle Bore Lathes

Large spindle bore lathes typically come with bore diameters between 80 mm and 130 mm. They are designed to handle longer and thicker workpieces, such as hydraulic cylinders, larger shafts, and industrial fittings. Manufacturers in the energy, machinery, and construction industries often rely on this class of lathe.

Extra Large Spindle Bore / Pipe Threading Lathes

For industries that require machining of pipes—such as oil and gas extraction—extra large spindle bore lathes offer bore sizes from 160 mm up to 300 mm or more. These machines are built for heavy-duty turning, threading, and processing of tubing, casings, drill pipes, and coupling sleeves.

External Factors That Affect Spindle Bore Performance

While the spindle bore size is an important specification, several external factors also influence how well a lathe performs when machining large-diameter or long workpieces. These factors determine the spindle’s stability, cutting accuracy, and overall machine lifespan. Understanding these aspects helps buyers evaluate whether a machine can maintain precision under demanding conditions.

One key factor is the spindle structure. A rigid, one-piece cast-iron spindle housing offers better vibration control and thermal stability, ensuring consistent accuracy during long machining cycles. Bearing configuration also plays a major role—high-quality tapered roller bearings and angular contact bearings provide the support needed for heavy cutting loads. Additionally, the heat dissipation design of the spindle affects long-term performance, especially during high-speed or continuous operations.

Another important consideration is the compatibility between spindle bore size and chuck selection. Large bores require correspondingly larger chucks, drawtubes, and hydraulic cylinders to maintain stability and clamping force. Improper matching can reduce accuracy or limit machining capacity. Buyers should ensure that the entire spindle–chuck system is optimized for the intended workpiece diameter to achieve the best performance.

How to Choose the Right Spindle Bore Size

When selecting a spindle bore, consider the following key points:

- Match the spindle bore to workpiece size: The spindle bore sets the maximum diameter of bar stock or tubes. Choosing the correct size ensures efficient machining and long-term flexibility.

- Small spindle bores for precision work: Ideal for electronics, mold-making, and general turning applications. They provide better rigidity and stability for smaller components.

- Large spindle bores for heavy-duty or long parts: Necessary for long shafts, hydraulic cylinders, thick-walled tubes, oil & gas pipes, automotive axles, and transmission parts.

- Consider automatic bar feeding: For high-volume production, ensure the spindle bore matches the bar feeder capacity to prevent bottlenecks.

- Plan for future requirements: Selecting a slightly larger bore than currently needed can provide flexibility for larger workpieces in the future.

Small Spindle Bore vs. Large Spindle Bore Lathes (Comparison Table)

The choice between a small spindle bore and a large spindle bore lathe directly affects machining performance, cost, and application suitability. Each configuration offers unique advantages depending on the workpiece size, precision requirements, and production environment. The comparison below helps buyers quickly understand which type of machine best matches their manufacturing needs.

| Feature | Small Spindle Bore | Large Spindle Bore |

|---|---|---|

| Typical Bore Size | 40–60 mm | 80–300 mm |

| Rigidity & Precision | Higher rigidity, best for fine-detail machining | Moderate rigidity, optimized for heavy-duty cutting |

| Compatible Workpieces | Small metal parts, electronics, molds | Pipes, long shafts, hydraulic cylinders, oilfield tubes |

| Machine Structure | Lighter spindle structure | Reinforced spindle housing and bearings |

| Production Use | Precision machining, small-batch work | Heavy-duty and large-diameter turning |

| Cost | Lower initial investment | Higher cost due to larger components |

| Main Industries | Electronics, general machining, mold-making | Oil & gas, automotive, hydraulic equipment, energy |

This comparison highlights that smaller spindle bores excel in precision, while larger spindle bores are essential for industries handling pipes or oversized materials. Buyers should select based on their primary machining tasks and long-term production goals.

Industries That Require Large Spindle Bore Lathes

Large spindle bore lathes are widely used in industries that regularly process long, thick-walled, or large-diameter materials. These machines offer the capacity and stability needed to handle heavy, oversized workpieces while maintaining efficiency and accuracy. As a result, they have become essential equipment for manufacturers operating in demanding industrial environments.

One of the primary users of large spindle bore lathes is the oil and gas industry. These machines are ideal for machining drill pipes, casings, tubing, and coupling sleeves. Their ability to handle extended materials makes them indispensable for pipe threading and heavy-duty turning. In the hydraulic equipment sector, large spindle bore lathes are equally important for manufacturing hydraulic cylinders, piston rods, and high-pressure pipeline components.

The automotive industry also benefits from large-bore lathes for producing components such as drive shafts, axle housings, and transmission parts. Additionally, industries involved in energy equipment, construction machinery, and precision metal fabrication rely on these machines to process larger structural elements. Their versatility and capacity make large spindle bore lathes a key asset for high-volume or heavy-duty production environments.

Why Choose Haisen for Large Spindle Bore CNC Lathes

Haisen is a leading Chinese CNC lathe manufacturer with over 20 years of expertise in producing high-speed, high-precision machines. When selecting a large spindle bore lathe, buyers benefit from Haisen’s strong research and development capabilities, advanced spindle engineering, and rigorous quality control. Each machine is designed to provide optimal rigidity, thermal stability, and long-term performance, ensuring that even heavy-duty turning and pipe threading operations are handled efficiently and accurately.

In addition to superior machine design, Haisen offers comprehensive support for international customers. Their machines have been exported to countries including Russia, UK, Peru, Ukraine, Turkey, Colombia, Brazil, Argentina, Malaysia, and various African markets. Customers can rely on fast delivery, lifetime technical service, and flexible customization options to match specific workpiece requirements. By choosing Haisen, manufacturers gain a trusted partner capable of providing reliable, high-quality CNC solutions for a wide range of industrial applications.

Conclusion

The spindle bore is one of the most critical specifications when selecting a CNC lathe, as it determines the maximum workpiece diameter, machining flexibility, and overall production efficiency. Understanding the importance of spindle bore size helps manufacturers choose the right lathe for their specific applications, whether they are working with precision components, long shafts, or large-diameter pipes.

Haisen’s expertise in producing high-quality CNC lathes with large spindle bores ensures that customers receive machines capable of meeting demanding industrial requirements. With advanced engineering, robust design, and comprehensive support, Haisen provides reliable solutions for industries such as oil and gas, automotive, hydraulic equipment, energy, and precision mold manufacturing. Choosing Haisen means investing in both machine performance and a trusted partner committed to enhancing the competitiveness of your production.