In the realm of precision manufacturing, the heavy duty lathe machine stands as a cornerstone of industrial machining, delivering unparalleled power, precision, and versatility. These robust machines are designed to handle large-scale, high-volume tasks that demand exceptional accuracy and durability. Whether you're shaping massive metal components for aerospace, crafting intricate parts for automotive industries, or fabricating heavy-duty shafts for renewable energy systems, a heavy duty lathe machine is an indispensable tool. In this comprehensive guide, we’ll explore what a heavy duty lathe machine is, its key features, applications, and why it’s a game-changer in modern manufacturing.

Defining the Heavy Duty Lathe Machine

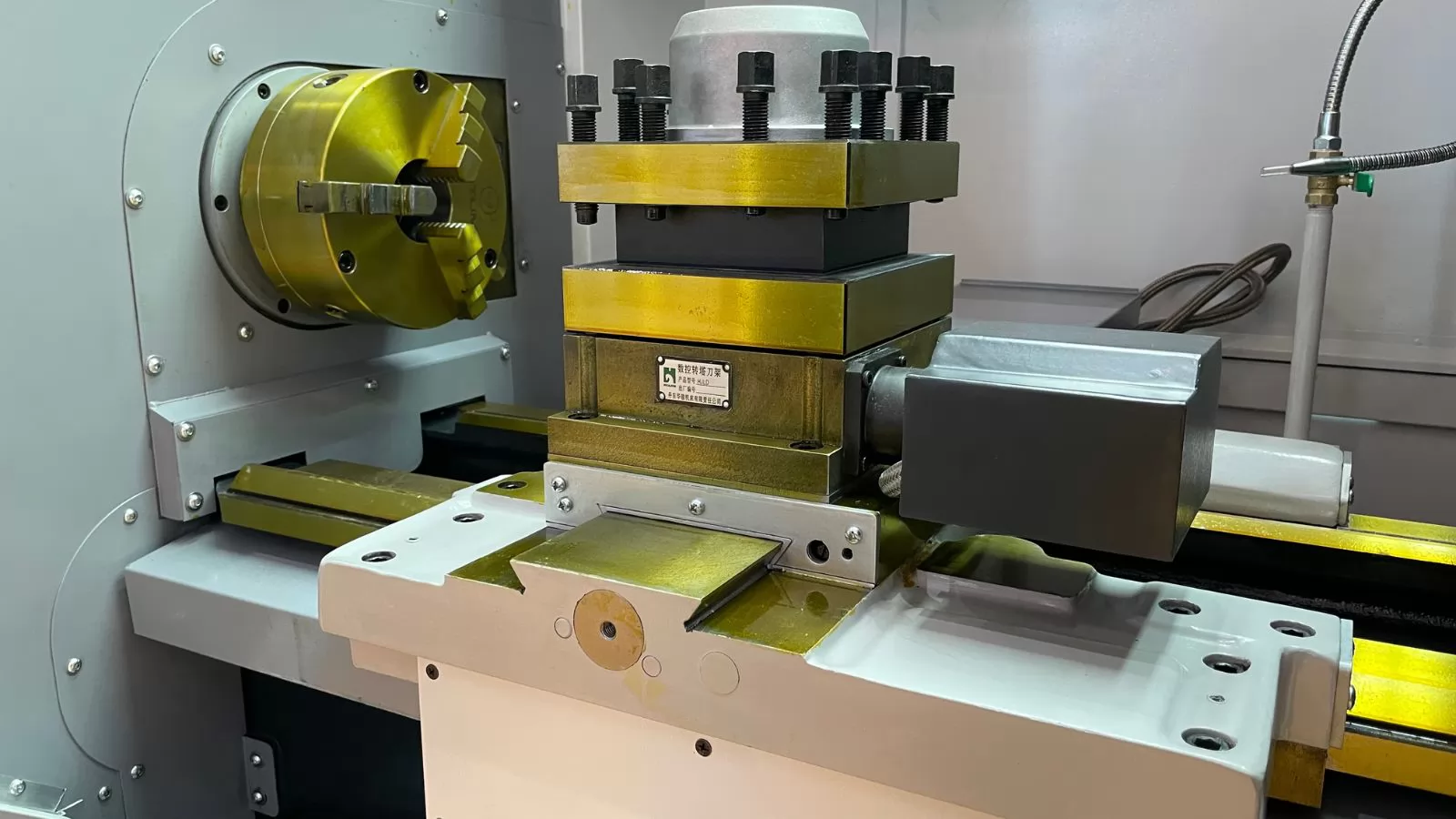

A heavy duty lathe machine is a powerful, computer-controlled or manually operated machine tool designed to shape large, robust workpieces by rotating them against a cutting tool. Unlike light or medium-duty lathes, which cater to smaller, less demanding tasks, heavy duty lathes are engineered to handle workpieces weighing from 16 to 63 tons, with swing-over-bed capacities ranging from 630mm to 1600mm . These machines are typically constructed from high-grade materials like cast iron and steel, ensuring stability, vibration resistance, and long-term durability even under intense operational stress.

The core function of a heavy duty lathe is to perform turning operations, where the workpiece rotates on its axis while a stationary cutting tool removes material to create cylindrical shapes, threads, or intricate geometries. With advancements in Computer Numerical Control (CNC) technology, modern heavy duty lathes offer automated precision, reducing human error and enabling complex machining tasks with minimal operator intervention.

Key Fact: Heavy duty lathe machines can process a wide range of materials, including stainless steel, brass, nickel, tantalum, and even non-metallic materials like wood and plastics, making them highly versatile for industrial applications .

Key Features of Heavy Duty Lathe Machines

Heavy duty lathe machines are distinguished by their advanced engineering and robust design, tailored to meet the demands of large-scale manufacturing. Here are the standout features that set them apart:

- Robust Construction: Built with stress-relieved cast iron beds and induction-hardened guideways, these machines offer exceptional rigidity and longevity, capable of withstanding high-pressure machining tasks .

- High Torque and Spindle Power: Equipped with high-torque inverter motors and dynamically balanced spindles, heavy duty lathes deliver superior cutting power, even at low RPMs, ideal for machining large-diameter parts .

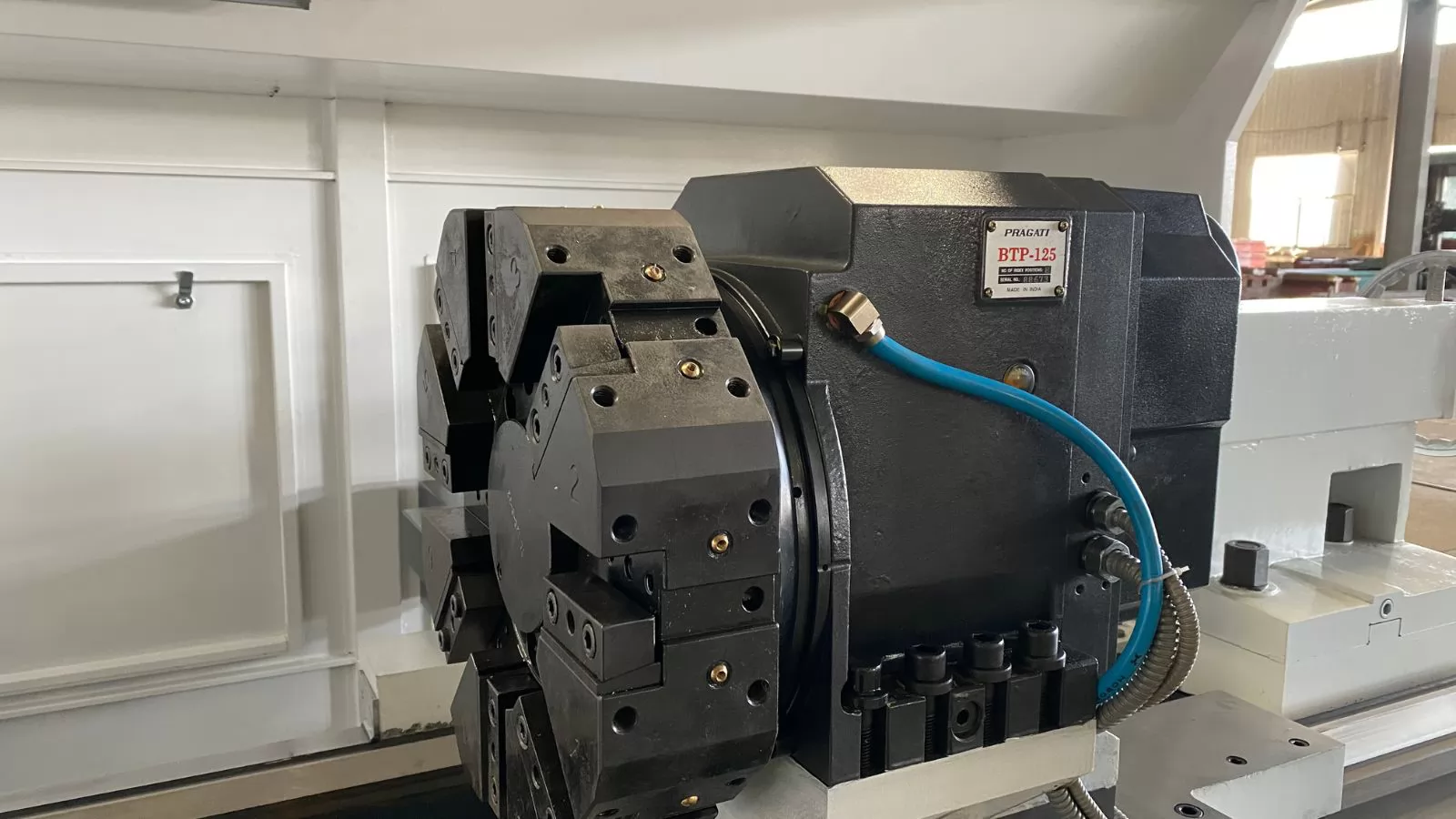

- Multi-Axis Capabilities: Modern CNC heavy duty lathes feature multi-axis control, enabling complex operations like threading, grooving, and taper cutting with high precision.

- Advanced Control Systems: CNC lathes are integrated with sophisticated software, allowing for programmable tool paths, real-time monitoring, and automated feedback systems to ensure consistent accuracy .

- Versatile Tooling: Many heavy duty lathes come with dual turrets accommodating up to 24 tool stations, enabling simultaneous operations and reducing setup times .

- Coolant Systems: Equipped with large coolant tanks, these machines maintain optimal temperatures during heavy metal processing, ensuring smooth operation and extended tool life.

Applications of Heavy Duty Lathe Machines

Heavy duty lathe machines are vital across a wide array of industries due to their ability to handle large, complex workpieces with precision. Some key applications include:

- Aerospace: Manufacturing turbine blades, landing gear components, and engine parts that require tight tolerances and high durability.

- Automotive: Producing gearbox cases, brake disks, and rack-and-pinion systems for vehicles, ensuring consistent quality in batch production .

- Oil and Gas: Machining large shafts, rotors, and stators for drilling equipment and submersible pumps .

- Renewable Energy: Crafting components like wind turbine shafts, nacelle spindles, and hydroelectric turbine wheels, which demand precision and reliability .

- Shipbuilding and Mining: Shaping heavy-duty components like propeller shafts and mining equipment parts, designed to withstand extreme conditions.

Evolution of Heavy Duty Lathe Machines

The journey of heavy duty lathe machines traces back to ancient times, with evidence of rudimentary lathes used by Egyptians around 1300 BC . These early machines, often manually operated, were limited by human skill and prone to errors. The introduction of CNC technology in the 20th century marked a pivotal shift, automating processes and enhancing precision .

Today’s heavy duty lathes incorporate cutting-edge innovations, such as:

- Next-Generation CNC Controls: Enabling real-time adjustments and predictive maintenance.

- Automation and Robotics: Reducing setup times and improving efficiency for high-volume production.

- 3D Printing Integration: Enhancing prototyping capabilities for custom components .

These advancements have transformed heavy duty lathes into highly efficient, precise, and reliable tools, making them indispensable in modern manufacturing.

Why Choose a Heavy Duty Lathe Machine?

Investing in a heavy duty lathe machine offers numerous benefits for manufacturers aiming to stay competitive:

- Precision and Accuracy: Automated CNC systems ensure consistent results, minimizing material waste and rework.

- Efficiency: High-speed spindles and multi-axis capabilities reduce machining time, boosting productivity.

- Versatility: Capable of processing diverse materials and shapes, from cylindrical surfaces to complex threads.

- Durability: Robust construction ensures long-term reliability, even in demanding environments.

- Cost-Effectiveness: Reduced labor costs and high output make these machines a cost-efficient choice for large-scale production.

Pro Tip: When selecting a heavy duty lathe, consider the manufacturer’s reputation, after-sales support, and customization options to ensure the machine meets your specific needs .

How to Choose the Right Heavy Duty Lathe Machine

Selecting the ideal heavy duty lathe machine requires careful consideration of your operational needs. Here are key factors to evaluate:

- Workpiece Size and Weight: Ensure the machine’s swing-over-bed and load capacity align with your project requirements.

- Machining Capabilities: Look for features like multi-axis control, threading options, and taper attachments for versatility.

- Automation Level: CNC lathes are ideal for high-precision, high-volume tasks, while manual lathes suit custom, low-volume jobs.

- Manufacturer Support: Choose reputable manufacturers like Yash Machine Tools or Alphaturn, known for quality and reliable service .

- Budget and ROI: Balance initial costs with long-term savings from efficiency and durability.

Conclusion

The heavy duty lathe machine is a powerhouse in modern manufacturing, combining strength, precision, and versatility to meet the demands of industries ranging from aerospace to renewable energy. With robust construction, advanced CNC technology, and the ability to handle large, complex workpieces, these machines are essential for high-volume, high-precision production. By understanding their features, applications, and selection criteria, manufacturers can harness the full potential of heavy duty lathes to drive efficiency and innovation.

Ready to elevate your manufacturing process? Explore top-tier heavy duty lathe machines from trusted manufacturers and invest in a tool that delivers unmatched performance and reliability.