The tailstock is an essential auxiliary unit used on lathes, CNC turning centers, and specialized machining equipment to support the free end of a workpiece. Although it is mechanically simple compared with other machine-tool components, the tailstock plays a decisive role in machining accuracy, rigidity, and stability—especially when working with long, slender, or heavy shafts that cannot maintain their own stiffness during rotation. Without a properly aligned and correctly selected tailstock, even a precision lathe can experience chatter, bending deformation, poor surface finish, or dimensional inaccuracies.

In industrial manufacturing environments, machinists rely on the tailstock to counteract cutting forces, reduce runout, and maintain concentricity between the spindle axis and the workpiece. It achieves this by holding a center (either live or dead), a drill chuck, or other axial tooling to provide firm and precise axial support. When machining parts such as transmission shafts, hydraulic cylinder rods, motor rotors, turbine shafts, or long pipe sections, the use of a tailstock is not optional—it is a fundamental requirement for quality-controlled production.

This article provides:

- Provides an overview of tailstock components and working principles.

- Explains different tailstock types and their applications.

- Outlines key selection criteria for choosing the right tailstock.

- Highlights maintenance and troubleshooting best practices.

- Guides manufacturers in improving precision, rigidity, and efficiency.

Core Components of a Tailstock: Structure, Functions, and Engineering Design

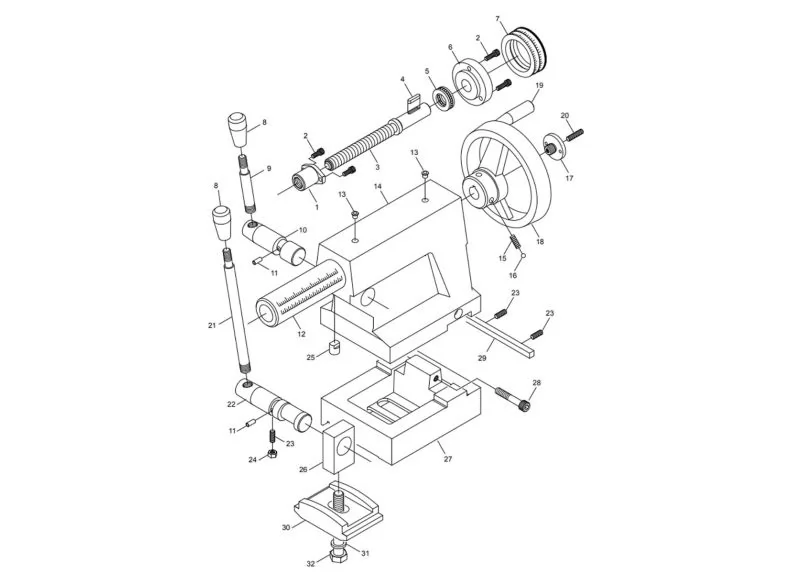

A tailstock may appear simple at first glance, but it is built from several precisely engineered components that work together to ensure rigidity, alignment, and reliable axial support. Understanding each structural element is essential for selecting the right tailstock and diagnosing performance issues that may arise during machining. Below is a detailed breakdown of the primary components found in most tailstock assemblies, from manual units to advanced CNC-controlled systems.

1. Base and Body

The tailstock base is the foundation of the entire assembly. It slides along the machine’s bedways and must maintain perfect contact to ensure stability during cutting operations. The base is typically manufactured from high-strength cast iron or alloyed steel to minimize vibration and maintain geometric accuracy over long-term use. Its surface is ground or scraped to match the lathe bed profile, ensuring optimal alignment and smooth movement. Any wear or misfit in this area can directly affect the workpiece’s concentricity.

2. Quill (Barrel) and Spindle Sleeve

The quill—also known as the barrel or spindle sleeve—is a hollow cylindrical tube that extends and retracts to apply axial pressure on the workpiece or tool. It is usually equipped with a Morse taper (MT1, MT2, MT3, etc.), allowing quick installation of centers, drill chucks, or tap holders. The internal and external surfaces of the quill are precision ground for extremely low runout, and most quills incorporate an anti-rotation mechanism to prevent twisting during drilling operations. The quality of the quill directly influences the accuracy and stability of the machining process.

3. Tailstock Center

The center is the most recognizable part of a tailstock. A dead center is made from hardened steel and remains stationary, relying on lubrication to prevent overheating. A live center, on the other hand, rotates with the workpiece via internal bearings, offering smoother operation and reduced friction. Choosing between a live and dead center depends on the cutting forces, rotational speed, and required precision level. High-speed and heavy-duty turning almost always benefits from a high-quality live center with sealed bearings.

4. Handwheel, Feed Screw, and Locking Mechanisms

The handwheel controls the axial movement of the quill through a precision feed screw, allowing fine adjustments during setup and machining. The tailstock also includes multiple locking mechanisms: one to secure the quill position and another to clamp the entire tailstock body onto the machine bed. Hydraulic or pneumatic systems may replace manual locks in more advanced models, delivering consistent clamping force and significantly improving repeatability.

Together, these components work in harmony to ensure that the tailstock delivers stable, accurate, and repeatable support, even under heavy cutting loads. The engineering integrity of each part directly impacts machining performance, making component quality a key consideration during selection.

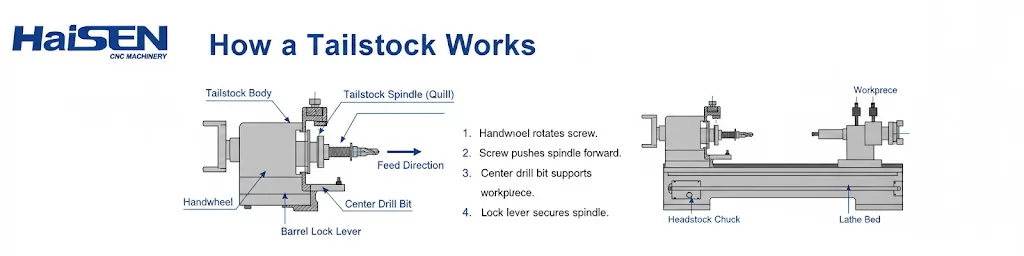

How a Tailstock Works: Mechanics & Alignment Principles

The primary function of a tailstock is to provide a supporting force that keeps a long or flexible workpiece stable during machining. Unlike the headstock, which drives rotation, the tailstock applies steady, adjustable pressure from the opposite end. This simple mechanical concept dramatically increases machining accuracy, minimizes tool deflection, and prevents workpiece vibration.

A tailstock operates through a quill (also known as a spindle) that can move forward and backward using a handwheel or CNC-controlled mechanism. When the quill advances, it presses a live center or tooling attachment against the workpiece. As the machine begins rotating, the applied axial force keeps the workpiece securely centered, ensuring it does not bend or shift under cutting loads. This is especially critical when turning shafts, tubes, axles, spindles, or any workpiece whose length is significantly greater than its diameter.

Alignment is a key principle in tailstock functionality. For accurate machining, the tailstock centerline must be perfectly aligned with the headstock spindle axis. Even minor misalignment leads to tapering, chatter, surface irregularities, and increased tool wear. High-quality tailstocks include fine-tuning mechanisms that allow operators to make micro-adjustments horizontally or vertically. Some advanced CNC lathes provide automatic alignment compensation to maintain precision throughout the machining cycle.

During cutting, the tailstock’s applied pressure must also be properly calibrated. Too little pressure results in poor support, causing the workpiece to deflect. Excessive pressure, on the other hand, increases friction and can overheat the center tip, especially with dead centers. This is why many machinists prefer live centers for high-speed turning, as their internal bearings reduce heat and eliminate scoring on the workpiece end.

Overall, a tailstock works as a stabilizing force that transforms a potentially unstable machining setup into a secure and high-precision environment. By maintaining alignment, applying consistent axial pressure, and reducing vibration, the tailstock enhances machining accuracy, tool life, and final product quality—making it an essential component in both manual and CNC lathes.

Types of Tailstocks and Their Applications

Tailstocks come in several designs to accommodate different machine configurations, workpiece sizes, and machining requirements. While the basic purpose remains the same—supporting the workpiece—the structural variations provide flexibility for both conventional and advanced machining operations. Understanding these types helps users select the most suitable model for their lathe or turning center.

1. Manual Tailstocks

Manual tailstocks are the most common type found on engine lathes and smaller CNC machines. They use a handwheel to advance and retract the quill and typically offer a locking mechanism to secure the tailstock body in place. These tailstocks are simple, durable, and cost-efficient, making them ideal for general-purpose machining tasks such as shaft turning, drilling, and reaming.

2. Hydraulic Tailstocks

Hydraulic tailstocks are used in heavy-duty or automated machining environments where consistent axial force is required. The hydraulic system delivers uniform pressure, enabling precise support even during aggressive cutting or high-speed operations. These tailstocks are common on CNC turning centers, large lathes, and machines handling oversized workpieces where manual force would be insufficient or inconsistent.

3. Programmable CNC Tailstocks

CNC tailstocks integrate with the machine's control system, automatically positioning themselves according to programmed commands. This eliminates manual intervention, reduces setup time, and ensures repeatable accuracy. CNC tailstocks are essential in high-efficiency production lines, where precision, speed, and automation are top priorities. They are especially useful for complex turning processes involving multiple diameters or variable lengths.

4. Fixed Tailstocks

Fixed tailstocks are rigid units that do not slide along the machine bed. They are typically installed on specialty or custom-built machines designed for a specific type of workpiece. Because of their immovable structure, fixed tailstocks offer exceptional stability but limited flexibility. They are often used in high-precision environments requiring zero positional drift.

Applications Across Industries

Different tailstock types support a wide range of machining tasks. Manual tailstocks are common in repair shops and small factories, while hydraulic and CNC models are preferred in automotive, aerospace, and energy sectors due to their reliability and repeatability. Heavy industries—such as wind energy, mining equipment manufacturing, and oil pipeline production—often use reinforced tailstocks to support large-diameter, long-length components that demand extreme rigidity and precision.

In summary, the variety of tailstock designs ensures compatibility with nearly any machining scenario. Whether supporting short-run manual jobs or powering through high-volume CNC production, each type delivers the stability and alignment required for accurate turning operations.

How to Choose the Right Tailstock: A Practical Selection Guide

- Match the Tailstock to the Machine Type: Ensure compatibility with your lathe or turning center. Manual lathes typically use hand-operated tailstocks, while CNC machines often benefit from hydraulic or fully programmable models. Correct mounting dimensions, center height, and bed geometry alignment are crucial to prevent tapering errors and excessive wear.

- Evaluate Workpiece Length and Diameter: Long and thin workpieces require stronger tailstock support. Manual tailstocks are sufficient for lightweight workpieces, but heavy shafts, pipes, or flexible components may need hydraulic or reinforced tailstocks. Consider future machining requirements to avoid frequent upgrades.

- Determine the Required Axial Force: Tailstocks vary in the amount of thrust they can apply. High-speed cutting, deep drilling, or heavy turning may require higher axial force to prevent deflection. Hydraulic tailstocks provide consistent pressure, while CNC-controlled tailstocks allow precise force management for automated setups.

- Choose the Right Center and Tooling Compatibility: Tailstock performance depends on the center installed. Live centers are ideal for high-speed operations; dead centers suit slow-speed or grinding applications. Ensure spindle taper (MT2, MT3, MT4, etc.) matches existing tooling. Consider additional accessories such as drill chucks or tapping attachments based on workflow.

- Prioritize Adjustment Features and Ease of Use: Micro-adjustment features, quick-lock mechanisms, smooth quill movement, digital position indicators, and ergonomic controls enable faster and more accurate setups. Automation reduces downtime and operator error in high-production environments.

By selecting a tailstock that matches your machine, workpiece, and production goals, you ensure high-quality results, improved precision, and long-term reliability. A tailstock is not merely an accessory—it is a core component of efficient turning operations.

Tailstock Applications in Industrial Machining

Tailstocks play a crucial role across numerous machining environments, especially in industries where long, heavy, or flexible workpieces must be turned with maximum precision. While their core function is to provide axial support, the range of industrial applications is far broader. Modern manufacturing sectors rely on tailstocks to improve accuracy, reduce vibration, and maintain process stability during high-speed or heavy-duty operations.

1. Turning Long Shafts and Cylindrical Components

One of the most common applications is the machining of long shafts, rods, rollers, and axles. Without tailstock support, these workpieces would easily deflect under cutting forces, causing tapering and chatter. Industries such as automotive, industrial machinery, and precision equipment manufacturing rely heavily on tailstocks to produce straight, consistent surfaces along extended lengths.

2. Deep-Hole Drilling and Boring Operations

Tailstocks are essential when performing drilling or boring operations that require the workpiece to stay firmly aligned with the cutting tool. The tailstock ensures a stable axis, minimizing drift and improving hole concentricity. This is particularly important for producing hydraulic cylinders, engine components, and pressure vessel parts where tight tolerances are mandatory.

3. Heavy-Duty Machining for Energy and Construction Industries

Large-scale components used in wind energy, mining equipment, pipeline production, and marine engineering require robust support during machining. Reinforced hydraulic tailstocks are commonly used for thick-walled tubes, turbine shafts, and structural steel segments. Their ability to apply high, consistent axial force ensures reliable stability even under aggressive cutting conditions.

4. Precision Manufacturing in Aerospace and Defense

Aerospace components often combine high-strength materials with complex geometries, making stability during machining essential. Tailstocks help maintain perfect alignment for titanium, Inconel, and stainless-steel components that require precision turning over extended lengths. CNC-controlled tailstocks are particularly valuable in this field due to their repeatability and automation benefits.

5. Improving Surface Finish and Tool Life

By minimizing vibration and preventing workpiece bending, tailstocks significantly improve surface finish quality. This reduces the need for secondary finishing operations and extends the lifespan of cutting tools. For manufacturers focused on cost reduction, process consistency, and high output, the tailstock remains a key contributor to achieving predictable machining results.

Overall, tailstocks are indispensable across modern machining applications. Their ability to deliver stability, alignment, and precision enables manufacturers in multiple sectors to meet strict quality requirements and maintain competitive production efficiency.

Maintenance, Calibration, and Troubleshooting

Proper maintenance and calibration ensure that a tailstock performs reliably and consistently over long-term operation. The tables below provide a clear, easy-to-understand overview of essential care routines and common troubleshooting procedures. This format helps operators quickly identify issues, perform routine checks, and maintain optimal machining accuracy.

Routine Maintenance Checklist

| Maintenance Task | Frequency | Purpose |

|---|---|---|

| Clean quill and tailstock surfaces | Daily | Prevents dust buildup and ensures smooth travel |

| Lubricate quill and lead screw | Weekly | Reduces wear and ensures consistent movement |

| Check alignment with headstock | Monthly | Maintains machining accuracy and prevents taper issues |

| Inspect center (live or dead) | Before every job | Avoids overheating, scoring, and alignment errors |

| Check hydraulic pressure (if applicable) | Monthly | Ensures stable axial force during machining |

Calibration Guide

| Calibration Step | Description | Expected Result |

|---|---|---|

| Check horizontal alignment | Use a test bar to verify the tailstock centerline matches the spindle axis. | Straight turning with zero taper |

| Check vertical alignment | Measure center height differences using an indicator stand. | Prevents chatter and uneven cutting |

| Quill runout inspection | Rotate the quill and measure deviation using a dial indicator. | Ensures accurate tool-to-workpiece contact |

| Preload force adjustment | Set appropriate pressure for the center to avoid deflection or overheating. | Optimal support without excessive friction |

Troubleshooting Common Issues

| Problem | Possible Cause | Solution |

|---|---|---|

| Workpiece tapering | Tailstock misaligned horizontally or vertically | Recalibrate alignment; check center wear |

| Chatter or vibration | Insufficient axial force or worn center bearings | Increase pressure; replace or lubricate center |

| Overheating center tip | Using dead center at high RPM or too much pressure | Switch to live center; reduce preload |

| Quill sticking or rough movement | Lack of lubrication or debris inside quill housing | Clean and lubricate quill; inspect for scoring |

| Inaccurate drilling alignment | Tailstock offset; worn spindle taper | Realign tailstock; inspect and regrind taper if needed |

These tables provide machinists with a fast and efficient way to diagnose issues and maintain ideal operating conditions. By following structured maintenance and calibration steps, operators can extend the lifespan of their tailstock and ensure consistent machining precision across all turning operations.

Conclusion

Tailstock technology remains a fundamental, yet often underestimated, component of precision turning operations. Whether you are working with a simple manual lathe or a fully automated CNC turning center, the correct choice, proper setup, and regular maintenance of your tailstock will directly impact machining accuracy, surface finish quality, tool life, and production efficiency. For long, slender, or heavy workpieces — such as shafts, axles, hydraulic components, or tubular structures — tailstock support is not optional. It’s the difference between stable, repeatable machining and costly defects, rework, or scrap.

At Haisen, we combine decades of experience, rigorous manufacturing standards, and continuous innovation to deliver high-precision machine tools optimized for modern industrial demands. Whether you require a conventional manual lathe or a high-speed CNC turning center — equipped with robust, well-aligned tailstock support — Haisen offers a full range of solutions tailored to your application. Our machines are engineered for rigidity, reliability, and long-term performance, helping you achieve consistent quality and productivity in every production run.

If you’re evaluating a new lathe purchase, upgrading your existing equipment, or optimizing your turning processes for better surface finish, tighter tolerances, or higher throughput — consider investing in a high-quality tailstock. It’s a modest addition to your setup that can yield significant returns in precision, efficiency, and part quality.

Ready to upgrade or customize your turning setup with tailstock-supported lathe solutions from Haisen? Contact Haisen today — our team will help you select the right machine configuration, ensure tailstock alignment, and provide full technical support from purchase to after-sales.

Frequently Asked Questions (FAQ)

- Q: Do I always need a tailstock for turning operations?

- A: Not always. For short, rigid workpieces or when using a chuck at both ends, a tailstock may be unnecessary. However, for any workpiece with significant length-to-diameter ratio, or when machining long shafts, tubes, or rods, a tailstock is highly recommended to prevent deflection, chatter, or surface chatter.

- Q: How do I know if my tailstock alignment is correct?

- A: Use a test bar or indicator to check concentricity and verify that the tailstock centerline matches the spindle axis. Also check for taper or runout on a test workpiece. If you notice taper, vibration, or inconsistent surface finish, a re-alignment or recalibration may be needed.

- Q: When should I use a live center vs a dead center?

- A: For high-speed turning or heavy-duty operations, a live center (with bearings) is generally better because it rotates with the workpiece, reducing heat generation and friction. For slow-speed operations or when maximum rigidity is needed (e.g., during grinding or rough turning), a hardened dead center may suffice — provided it is properly lubricated.

- Q: How often should I perform tailstock maintenance?

- A: Light maintenance — cleaning surfaces and ensuring no chips or debris — should be done daily. Full lubrication, alignment checks, and inspection of the quill and center should be scheduled regularly (e.g., weekly or monthly depending on usage intensity) — especially when processing long or heavy workpieces.

- Q: Can Haisen supply tailstock-equipped lathes for specialized applications?

- A: Yes. Haisen produces a wide range of machines — from conventional manual lathes to heavy-duty CNC turning centers — and offers customization and automation solutions. We support applications across automotive, energy, oil & gas, mold manufacturing, and more.