_1767602307_WNo_1600d900.webp)

Introduction | Industry Overview

The global vertical machining center (VMC) market continues to grow steadily, driven by increasing demand for high-precision manufacturing across industries such as aerospace, automotive, mold making, and medical devices. Vertical machining centers are critical for achieving precise multi-axis operations, high repeatability, and efficient production workflows.

For engineers, production managers, and procurement specialists, selecting the right VMC manufacturer is not just about brand recognition—it involves understanding technical specifications, reliability, service support, and the alignment of machine capabilities with specific production needs. This article provides an objective overview of the top 10 VMC manufacturers in 2026, comparing their offerings and highlighting key considerations for buyers.

The purpose of this guide is to offer a clear, comprehensive reference for industry professionals. By organizing technical details, representative models, and application scenarios in one place, readers can make informed decisions while minimizing research time and uncertainty.

How to Choose a Vertical Machining Center Manufacturer | Buyer's Guide

Key Factors for Selection

Selecting the right vertical machining center (VMC) manufacturer requires careful consideration of several technical and operational factors. The most important elements include the control system, machine rigidity, precision and repeatability, automation capabilities, and service network.

The control system, such as Fanuc, Siemens, or proprietary software, determines machine responsiveness, programmability, and integration with other production equipment. Rigidity and structural stability are essential for maintaining accuracy during high-speed or heavy-duty operations. Precision and repeatability specifications ensure consistent part quality, which is critical in industries like aerospace or medical device manufacturing.

Automation and Industry 4.0 compatibility are increasingly important, as modern factories demand integration with robotic systems, tool changers, and real-time monitoring for efficient production. Finally, a reliable service network, including spare parts availability and local technical support, significantly reduces downtime and long-term operational costs.

Practical Tips

When evaluating VMC manufacturers, buyers should match machine capabilities to their specific production requirements. Small workshops may prioritize compact, cost-effective machines with basic automation, while mid-sized manufacturers might focus on multi-axis flexibility and moderate production speed. Large-scale or specialized industries, such as aerospace or heavy machinery, often require high-precision machines with advanced thermal compensation, automation, and full-service support.

Comparing manufacturers across these criteria helps identify machines that offer the best balance between performance, reliability, and total cost of ownership. Objective research, including reviewing technical datasheets, case studies, and industry reviews, ensures informed decisions without bias toward a particular brand.

Technical Comparison Table

To help buyers quickly understand the overall capabilities of leading vertical machining center manufacturers, the following table summarizes the core technical characteristics commonly found across their mainstream VMC product lines. These specifications are indicative ranges based on publicly available information and typical industry configurations. Exact values may vary depending on the specific model, machine size, customization options, and application requirements. Therefore, this comparison should be viewed as a practical reference for preliminary evaluation rather than a strict specification match. By reviewing these metrics in advance, users can form a clearer understanding of how different VMC brands position their machines in terms of performance, precision, and productivity.

| Manufacturer | Control System | Axis | Typical Worktable / Travel (X×Y×Z mm) | Spindle Speed (RPM) | Main Applications |

|---|---|---|---|---|---|

| JTEKT Machinery | Fanuc / Siemens | 3–5 | 500×400×400 – 1000×800×600 | 12,000 – 24,000 | Aerospace, Automotive, Mold Making |

| Kitamura Machinery | Fanuc / Mitsubishi | 3–5 | 400×300×300 – 800×500×500 | 10,000 – 20,000 | Mold Making, Medical Devices, Electronics |

| Mazak | Mazak Smooth Technology | 3–5 | 500×400×400 – 1200×800×700 | 12,000 – 20,000 | Aerospace, Automotive, General Manufacturing |

| Makino | Makino Proprietary CNC | 3–5 | 450×350×350 – 1000×600×500 | 12,000 – 24,000 | Aerospace, Automotive, Mold Making, Medical |

| DMG Mori | CELOS / Fanuc | 3–5 | 500×400×400 – 1200×800×700 | 12,000 – 24,000 | Aerospace, Automotive, Mold Making, General Manufacturing |

| DN Solutions | Fanuc | 3–5 | 400×300×300 – 800×500×500 | 10,000 – 18,000 | Small to Mid-Sized Precision Manufacturing |

| Okuma | OSP CNC | 3–5 | 500×400×400 – 1200×800×700 | 12,000 – 20,000 | Aerospace, Automotive, Mold Making |

| Haas Automation | Haas CNC | 3–5 | 400×300×300 – 1000×500×500 | 12,000 – 20,000 | Automotive, Aerospace, General Manufacturing |

| Komatsu NTC | Fanuc / Mitsubishi | 3–5 | 600×500×500 – 1500×1000×800 | 10,000 – 18,000 | Construction Equipment, Aerospace, Automotive, Energy |

| Flex Machine Tools | Fanuc / Siemens | 3–5 | 400×300×300 – 800×500×500 | 10,000 – 18,000 | Small and Medium Workshops, General Manufacturing |

| Haisen (HS-MachineTools) – Reference | Varies by model (Check official site) | 3–5 | Varies by model (Check official site) | Varies by model | General VMC applications, industrial machining |

Top 10 Vertical Machining Center Manufacturers

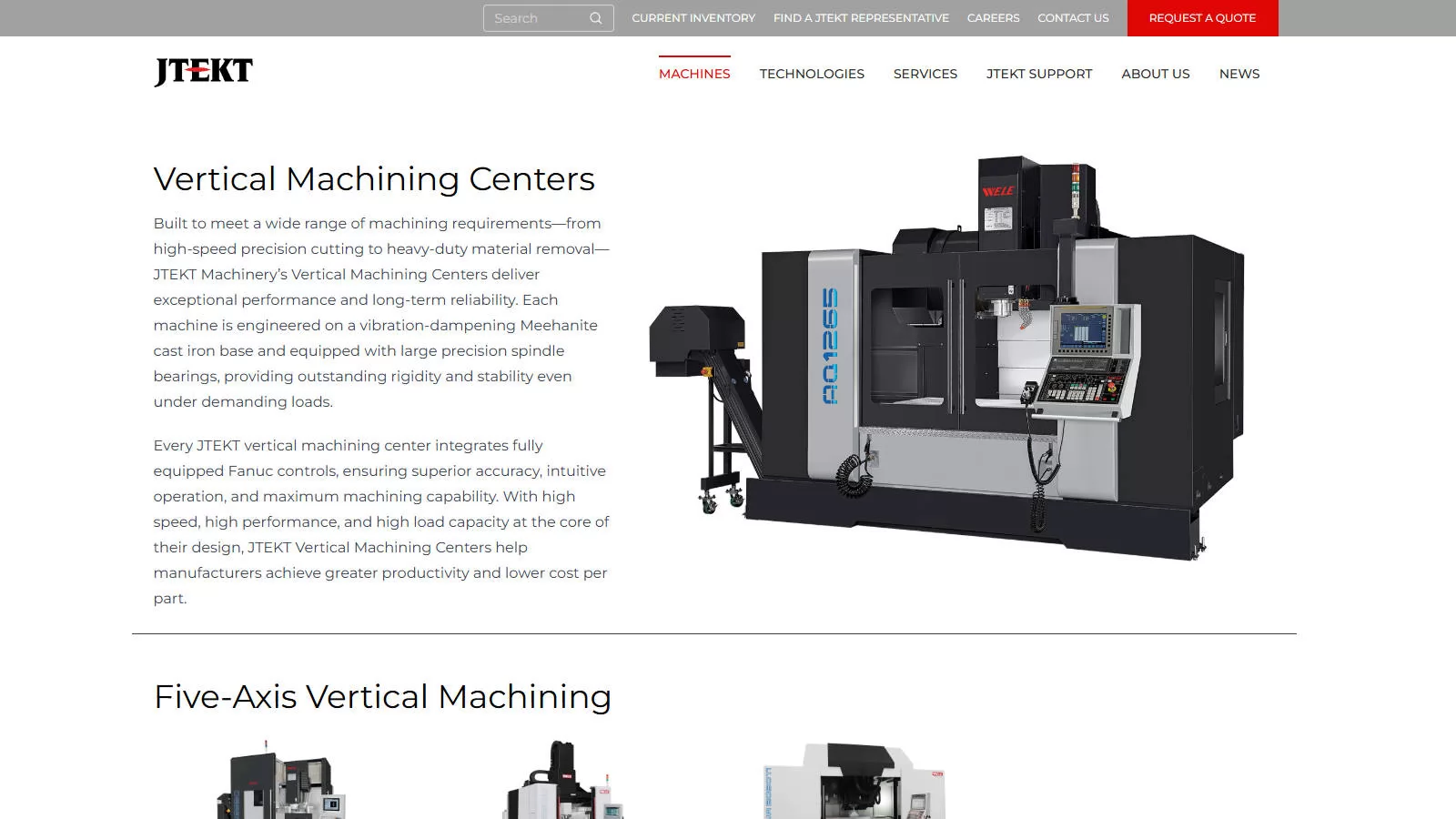

JTEKT Machinery

Company Overview: Headquartered in Japan, JTEKT Machinery is a leading manufacturer of high-precision vertical machining centers (VMCs) with decades of experience in the machine tool industry. The company focuses on rigidity, thermal stability, and consistent accuracy, serving aerospace, automotive, and mold-making sectors.

Key VMC Models:

- KT-C Series: Multi-axis machining, high-speed spindle, thermal compensation

- KT-V Series: Flexible configuration for precision and small-batch production

Technical Features:

- Fanuc or Siemens CNC control integration

- High repeatability and thermal stability for long production runs

- Compact design with high rigidity

Strengths:

- Reliable engineering and build quality

- Global service network covering Asia, Europe, and North America

- Ideal for precision component manufacturing and high-mix, low-volume operations

Considerations: JTEKT machines tend to have higher initial costs compared to entry-level brands, but offer long-term accuracy and reliability advantages.

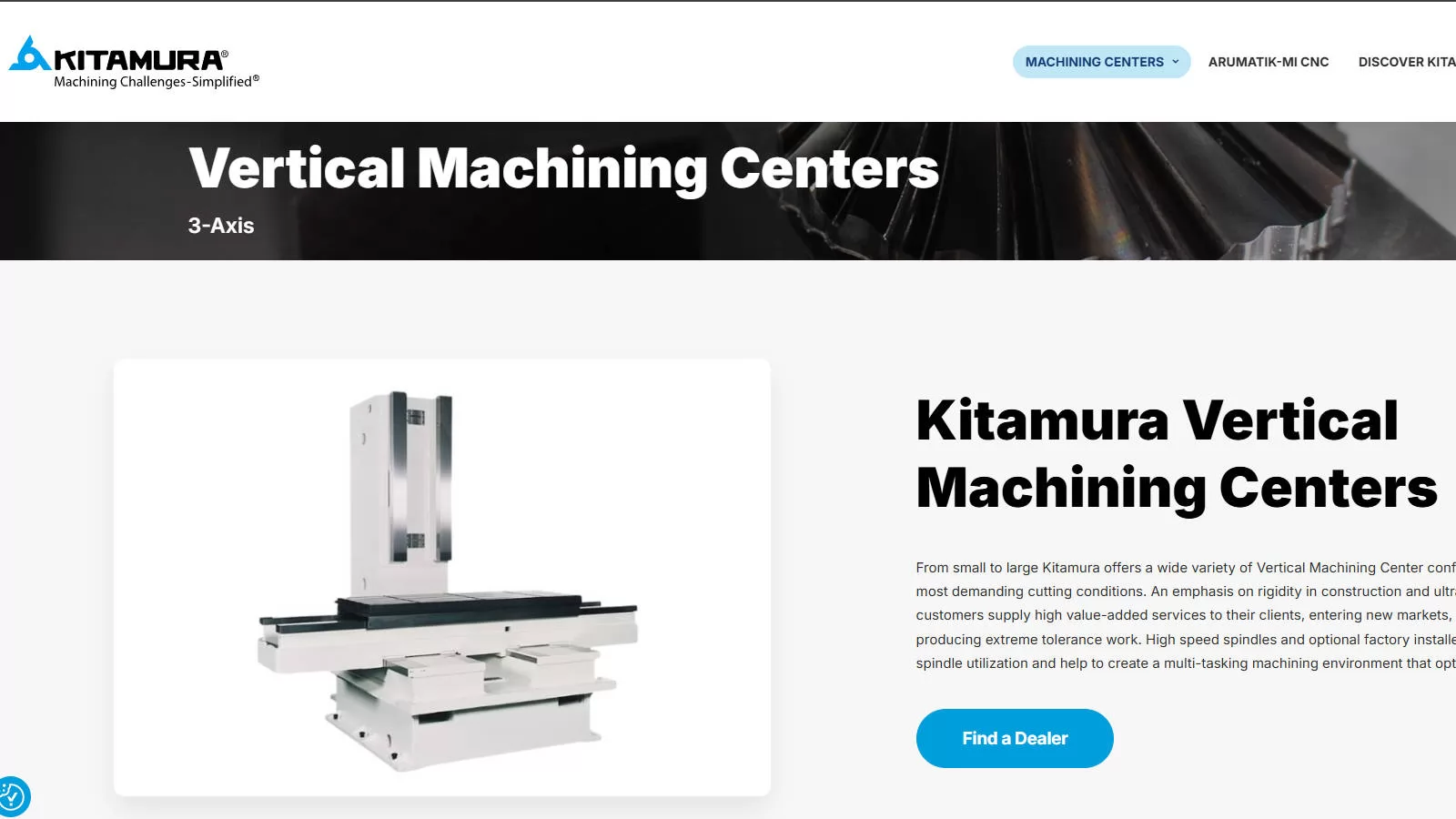

Kitamura Machinery

Company Overview: Kitamura Machinery, based in Japan, has over 90 years of experience in precision machine tools. The company specializes in compact and mid-sized vertical machining centers (VMCs) that excel in accuracy, stability, and ease of operation. Kitamura machines are widely used in mold making, medical device production, and electronics manufacturing.

Key VMC Models:

- Mycenter-HX Series: High-speed, high-rigidity machining for small to medium components

- Mycenter-3Xi Series: Multi-axis flexibility, ideal for complex geometries

Technical Features:

- Fanuc or Mitsubishi CNC systems

- High-speed spindles with thermal compensation

- Compact footprint suitable for limited floor space

Strengths:

- Exceptional precision and repeatability

- Strong performance in small-batch, high-mix production

- Reputation for durable and reliable machines

Considerations: Kitamura machines are generally mid- to high-priced; buyers should balance cost with precision requirements and intended production volume.

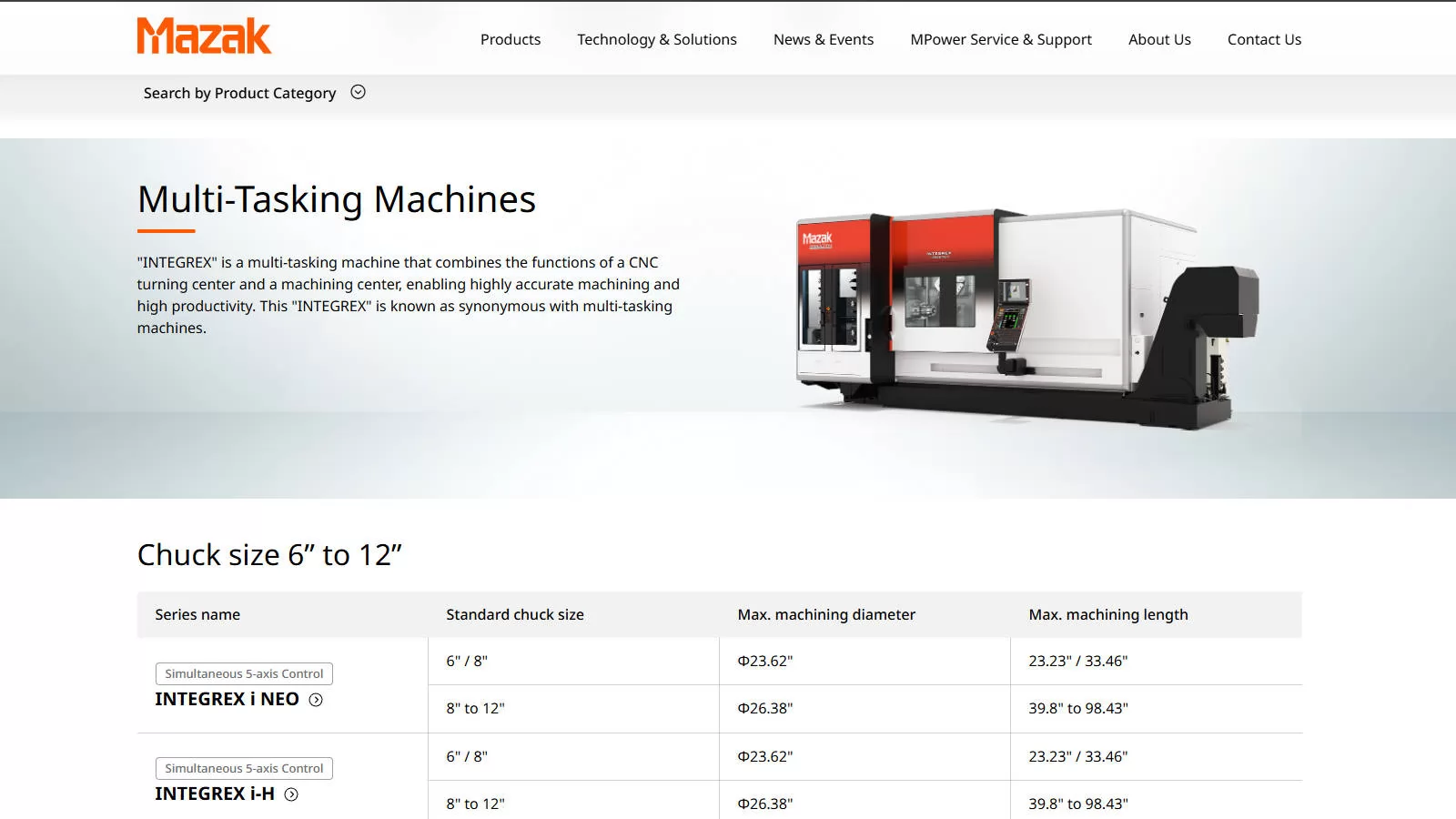

Mazak

Company Overview: Yamazaki Mazak, headquartered in Japan, is a globally recognized machine tool manufacturer known for its advanced vertical machining centers (VMCs) and multi-tasking machines. Mazak focuses on precision, flexibility, and automation, serving aerospace, automotive, and general manufacturing industries worldwide.

Key VMC Models:

- VARIAXIS i-Series: 5-axis machining for complex geometries and high-precision components

- VTC Series: Robust vertical machining centers suitable for high-volume production

Technical Features:

- Integrated Mazak Smooth Technology control system

- High-speed spindles with thermal compensation

- Flexible multi-axis capabilities for complex part machining

Strengths:

- Excellent flexibility and precision for high-mix production

- Advanced automation options for smart manufacturing

- Global service and support network

Considerations: Mazak machines tend to be premium-priced, and buyers should evaluate ROI based on production complexity and required throughput.

Makino

Company Overview: Makino, based in Japan, is a leading manufacturer of high-precision vertical machining centers (VMCs) and advanced machining solutions. The company is recognized for its focus on accuracy, rigidity, and productivity, serving industries such as aerospace, automotive, medical devices, and mold making.

Key VMC Models:

- PS Series: High-speed, high-rigidity machines optimized for precision components

- V33i / V56i Series: Flexible vertical machining centers for small- to medium-sized production runs

Technical Features:

- Makino proprietary control systems with thermal compensation

- High-speed spindles for reduced cycle times

- Exceptional structural rigidity for stable, precise machining

Strengths:

- High accuracy and repeatability even in complex operations

- Strong suitability for precision industries

- Global service network and technical support

Considerations: Makino machines are positioned in the premium segment; initial investment is higher, but the precision and long-term reliability provide significant value for demanding applications.

DMG Mori

Company Overview: DMG Mori is a global leader in machine tool manufacturing, with headquarters in Germany and Japan. The company produces high-precision vertical machining centers (VMCs) and multi-axis machines, combining advanced technology with global service capabilities. DMG Mori serves aerospace, automotive, mold making, and general manufacturing industries worldwide.

Key VMC Models:

- DMU Series: 5-axis and multi-axis machining for complex geometries

- CMX Series: High-speed vertical machining centers for small to medium parts

Technical Features:

- CELOS control system for integrated production management

- High-speed, high-rigidity spindles

- Thermal compensation and advanced vibration control for precision

Strengths:

- Comprehensive global service and support network

- High flexibility for both high-mix and high-volume production

- Strong reputation for innovation and reliability

Considerations: DMG Mori machines are premium-grade and may require higher initial investment; however, they offer long-term performance and advanced automation options suitable for demanding production environments.

DN Solutions

Company Overview: DN Solutions, originating from South Korea, specializes in high-performance vertical machining centers (VMCs) suitable for precision manufacturing and industrial production. The company focuses on durability, ease of use, and cost-effective solutions for small to mid-sized factories.

Key VMC Models:

- DNV Series: Compact VMCs for precision parts with high repeatability

- DNX Series: Flexible multi-axis machines for small-batch production

Technical Features:

- Fanuc CNC control integration

- High-speed spindles and rigid machine structure

- Thermal stability for consistent accuracy

Strengths:

- Good balance of cost and performance

- Reliable and durable machines for industrial applications

- Suitable for small-batch, high-mix production environments

Considerations: DN Solutions machines may not have as extensive a global service network as some larger brands, so buyers should consider local support availability when making purchasing decisions.

Okuma

Company Overview: Okuma, headquartered in Japan, is a leading manufacturer of vertical machining centers (VMCs) and multi-tasking machines. The company emphasizes “Single Source” solutions, integrating machine hardware, CNC control, and drive systems for optimized performance. Okuma serves aerospace, automotive, mold making, and general manufacturing industries globally.

Key VMC Models:

- MB-V Series: High-precision vertical machining centers with robust rigidity

- MU-V Series: Flexible multi-axis VMCs for complex part machining

Technical Features:

- Okuma proprietary OSP CNC control system

- High-speed spindles with thermal compensation

- Advanced rigidity and vibration control for consistent precision

Strengths:

- Fully integrated hardware and software solutions

- High accuracy and repeatability for complex components

- Global service network and support infrastructure

Considerations: Okuma machines are generally positioned in the premium segment, and initial investment may be higher; however, integrated control systems and reliable build quality offer long-term operational efficiency.

Haas Automation

Company Overview: Haas Automation, based in the United States, is one of the largest VMC manufacturers globally. Known for cost-effective and user-friendly machines, Haas focuses on providing reliable vertical machining centers for a wide range of industries, including automotive, aerospace, mold making, and general manufacturing.

Key VMC Models:

- VF Series: General-purpose vertical machining centers for small to medium parts

- UMC Series: 5-axis multi-tasking machines for complex components

Technical Features:

- Haas CNC control system with intuitive interface

- High-speed spindles and rigid construction

- Optional automation features such as pallet changers and robotic integration

Strengths:

- High value for money and accessible for small to mid-sized workshops

- Large service and parts network in North America

- Ease of use and straightforward maintenance

Considerations: While Haas machines offer excellent value, they may not match the high-end precision or advanced automation features of premium Japanese or German brands.

Komatsu NTC

Company Overview: Komatsu NTC, part of the Komatsu Group in Japan, specializes in vertical machining centers (VMCs) and heavy-duty machine tools. The company focuses on large-scale, high-precision machining solutions for industries such as construction equipment, aerospace, automotive, and energy.

Key VMC Models:

- NTC Series: Robust vertical machining centers for large parts and high-volume production

- NX Series: Flexible multi-axis machines with high rigidity and thermal stability

Technical Features:

- Fanuc or Mitsubishi CNC control systems

- High-speed, high-torque spindles for heavy-duty machining

- Enhanced rigidity and thermal compensation for precision on large workpieces

Strengths:

- Excellent performance for large-scale industrial components

- Strong global service and support network

- Durable, long-lasting machine construction

Considerations: Komatsu NTC machines are premium-grade and often require larger floor space and higher initial investment, making them more suitable for industrial-scale operations.

Flex Machine Tools

Company Overview: Flex Machine Tools, based in the United States, is a supplier of versatile vertical machining centers (VMCs) catering to small and medium-sized manufacturing businesses. The company emphasizes flexibility, a broad product range, and quick delivery options.

Key VMC Models:

- Flex VMC Series: General-purpose vertical machining centers for a variety of production needs

- Flex Multi-Axis Series: Multi-axis options for small-batch, complex component machining

Technical Features:

- Fanuc or Siemens CNC control integration

- High-speed spindles with moderate rigidity suitable for general machining

- Compact design for small to mid-sized workshops

Strengths:

- Broad selection of VMCs for different budgets and production scales

- Quick delivery and flexible configurations

- Good balance of performance and cost-effectiveness

Considerations: Flex Machine Tools may not offer the same high-end precision or advanced automation features as premium Japanese or German brands, so buyers should match machine capabilities to production requirements.

Industry Trends and Emerging Technologies in Vertical Machining Centers

The development of vertical machining centers is being driven by higher accuracy requirements, automation demand, and continuous improvements in CNC technology. Today, leading manufacturers are focusing not only on machine power and size, but also on stability, intelligence, and overall production efficiency.

Automation and Unmanned Manufacturing

- Integration with robots and pallet systems is becoming standard

- Factories are moving toward 24/7 continuous production

- Automation reduces dependence on operators while improving consistency

High-Precision and High-Speed Machining

- Better spindle technology and thermal control improve repeatability

- Machines are designed to handle harder materials and tighter tolerances

- Applications such as aerospace and moldmaking continue to drive innovation

Smart CNC and Digital Connectivity

- Process monitoring and adaptive machining are increasingly common

- Remote diagnostics help reduce downtime

- Data connectivity supports Industry 4.0 production environments

Sustainability and Long-Term Operating Efficiency

- Energy-efficient drives and lubrication systems

- Longer-life components and improved reliability

- Focus on lowering total lifecycle cost

Overall, the market is moving toward smarter, more stable, and more automated VMC solutions. This means buyers today should evaluate not only cutting capability, but also control technology, automation compatibility, and long-term operating cost when selecting a machine.

Conclusion

The global market for vertical machining centers continues to evolve as manufacturers integrate higher levels of automation, precision control, and digital intelligence into their product lines. For buyers, the key consideration is no longer just machine size or spindle power, but how well a VMC fits long-term production goals, operating conditions, and budget requirements.

By understanding current industry trends, key performance indicators, and the strengths of leading vertical machining center manufacturers, users are better equipped to make informed purchasing decisions. Each brand offers different advantages in areas such as rigidity, precision, automation capability, software functionality, and lifecycle support, meaning the most suitable choice will vary depending on application needs.

This article aims to provide a clear, structured overview of the top VMC suppliers and the essential factors to consider when selecting equipment. As technology continues to develop, vertical machining centers will remain a core solution in modern precision manufacturing, supporting industries ranging from automotive and aerospace to moldmaking and general engineering.