In today's competitive manufacturing landscape, choosing the right CNC milling machine supplier is critical for businesses looking to enhance precision, efficiency, and productivity. With numerous options available globally, identifying the top suppliers who offer reliable machines, excellent customer service, and comprehensive technical support can be challenging.

This comprehensive guide examines the top 10 CNC milling machine suppliers worldwide, including our own Haisen Machine Tools, to help you make an informed decision for your manufacturing needs. We'll analyze their strengths, specialties, and what makes each unique in the global market.

Table of Contents

- Understanding CNC Milling Machines

- Evaluation Criteria for Top CNC Suppliers

- DMG MORI

- Haas Automation

- Makino

- Okuma Corporation

- Mazak Corporation

- Doosan Machine Tools

- GROB Group

- Hurco Companies

- Matsuura Machinery

- Hermle AG

- Recommand Manufacturer: Haisen Machine Tools

- Comparison of Top Suppliers

- How to Choose the Right CNC Milling Machine Supplier

- Future Trends in CNC Milling Technology

- Conclusion

Understanding CNC Milling Machines

CNC (Computer Numerical Control) milling machines are sophisticated manufacturing tools that use computerized controls to operate and manipulate machine tools through programmed commands. These versatile machines are crucial in modern manufacturing for creating complex parts with high precision.

CNC milling machines typically come in various configurations, including vertical machining centers (VMCs), horizontal machining centers (HMCs), and multi-axis machines offering 4-axis or 5-axis capabilities. The advancement of CNC milling technology has revolutionized manufacturing processes by allowing for greater automation, precision, and repeatability.

Key Components of Modern CNC Milling Machines

- Control Systems: Advanced CNC controllers with user-friendly interfaces

- Spindle Technology: High-speed spindles for improved cutting performance

- Automatic Tool Changers (ATC): For rapid tool switching during operations

- Bed and Frame Design: Rigid construction to minimize vibration and maintain precision

- Coolant Systems: Efficient cooling solutions for extended tool life and better surface finish

- Axis Movement: Linear guides and ball screws for smooth, accurate movement

Evaluation Criteria for Top CNC Suppliers

When evaluating CNC milling machine suppliers, several critical factors determine their ranking and suitability for specific manufacturing needs. Our assessment of the top suppliers considers:

- Product Range and Versatility: Variety of machine types and capabilities

- Build Quality and Precision: Machine accuracy, repeatability, and rigidity

- Technological Innovation: Integration of cutting-edge technology and Industry 4.0 features

- After-Sales Support: Quality of technical support, service network, and spare parts availability

- Value for Money: Cost-effectiveness relative to features and performance

- Global Presence: Availability of machines and support in different regions

- User Experience: Feedback from customers and industry reputation

- Training and Resources: Available educational resources for optimal machine usage

DMG MORI

DMG MORI

DMG MORI, formed by the merger of German DMG and Japanese MORI SEIKI, stands as one of the world's largest manufacturers of cutting machine tools. With a rich heritage dating back over 70 years, DMG MORI has established itself as a premium supplier known for its technological innovation and high-precision machines.

Strengths

- Extensive range of advanced milling solutions

- Industry-leading precision and build quality

- Cutting-edge control systems and software

- Comprehensive global service network

- Strong focus on automation and Industry 4.0

Considerations

- Premium pricing structure

- Complex machines may require specialized training

DMG MORI's extensive product range includes universal milling machines, vertical machining centers, horizontal machining centers, and 5-axis milling machines. Their machines are particularly favored in aerospace, automotive, and medical industries where high precision is paramount.

Haas Automation

Haas Automation

Founded in 1983, Haas Automation has grown to become America's largest machine tool builder. Known for its cost-effective, reliable CNC machines, Haas has democratized CNC technology by offering high-quality machines at accessible price points.

Strengths

- Strong value proposition with competitive pricing

- Simple, user-friendly control systems

- Extensive dealer network and technical support

- Standardized parts and components for easier maintenance

- Made in USA quality with global support

Considerations

- Fewer customization options compared to some premium brands

- Basic models may lack advanced features available from other suppliers

Haas offers a comprehensive range of vertical machining centers, horizontal machining centers, CNC lathes, and rotary products. Their machines are particularly popular in education, job shops, and small to medium manufacturing operations.

Makino

Makino

Established in 1937, Makino is a Japanese manufacturer renowned for its high-precision machine tools. The company has built a reputation for engineering excellence and technological innovation, particularly in high-speed milling and die/mold applications.

Strengths

- Industry-leading precision and surface finish quality

- Advanced thermal management systems

- Specialized solutions for challenging materials

- Excellent long-term reliability and durability

- Comprehensive application engineering support

Considerations

- Higher initial investment cost

- Complex technology may require specialized operator training

Makino specializes in horizontal and vertical machining centers, 5-axis milling machines, graphite machining centers, and wire EDM machines. Their technology excels in aerospace, automotive, die/mold, and medical device manufacturing.

Okuma Corporation

Okuma Corporation

With over 100 years of experience, Okuma is a Japanese machine tool manufacturer known for its "single-source" approach, developing and manufacturing all critical components in-house. This approach ensures exceptional quality control and integration between mechanical and control systems.

Strengths

- Proprietary OSP control system with user-friendly operation

- Excellent thermal stability with Thermo-Friendly Concept

- Robust construction for long-term accuracy

- Open architecture allowing for customization

- Comprehensive intelligent technology suite

Considerations

- Premium pricing structure

- Proprietary control system requires specific training

Okuma offers a wide range of vertical and horizontal machining centers, multi-tasking machines, 5-axis machines, and grinding machines. Their solutions are particularly valued in industries requiring high precision and reliability, such as aerospace, energy, and heavy equipment manufacturing.

Mazak Corporation

Mazak Corporation

Yamazaki Mazak Corporation, founded in 1919, has grown into one of the world's largest manufacturers of CNC machine tools. Known for pioneering multi-tasking technology and factory automation systems, Mazak continues to lead in manufacturing innovation.

Strengths

- Innovative multi-tasking and hybrid manufacturing solutions

- Advanced MAZATROL conversational programming system

- Comprehensive global service and support network

- Strong focus on smart factory technology

- Excellent application versatility

Considerations

- Premium pricing for advanced models

- Some advanced features may require specialized training

Mazak's product lineup includes vertical machining centers, horizontal machining centers, multi-tasking machines, 5-axis machines, and hybrid multi-tasking systems. Their machines serve diverse industries, from aerospace and automotive to medical and general manufacturing.

Doosan Machine Tools

Doosan Machine Tools

Doosan Machine Tools (formerly Doosan Infracore Machine Tools) is a South Korean manufacturer known for its robust and reliable CNC machines. With a history dating back to 1976, Doosan has established itself as a global player offering excellent value and performance.

Strengths

- Strong performance-to-price ratio

- Robust construction and reliability

- Wide range of machine sizes and configurations

- Growing global service network

- Excellent customer support reputation

Considerations

- Less extensive automation options compared to some premium brands

- Service network still expanding in some regions

Doosan offers horizontal machining centers, vertical machining centers, multi-tasking turning centers, and 5-axis machines. Their machines are particularly popular in general manufacturing, job shops, and automotive supply chains.

GROB Group

GROB Group

GROB, a German machine tool manufacturer founded in 1926, specializes in highly customized manufacturing systems and universal machining centers. Known for their innovative 5-axis technology and automotive production systems, GROB offers solutions for complex machining applications.

Strengths

- Advanced 5-axis machining technology

- Unique horizontal spindle design for better chip evacuation

- Excellent thermal stability and precision

- Strong automation integration capabilities

- Comprehensive training and technical support

Considerations

- Higher price point for specialized machines

- Less extensive model range for standard applications

GROB's product range includes universal machining centers, 5-axis machining centers, and complete production systems. Their machines are particularly valued in aerospace, automotive, and medical industries requiring complex part production.

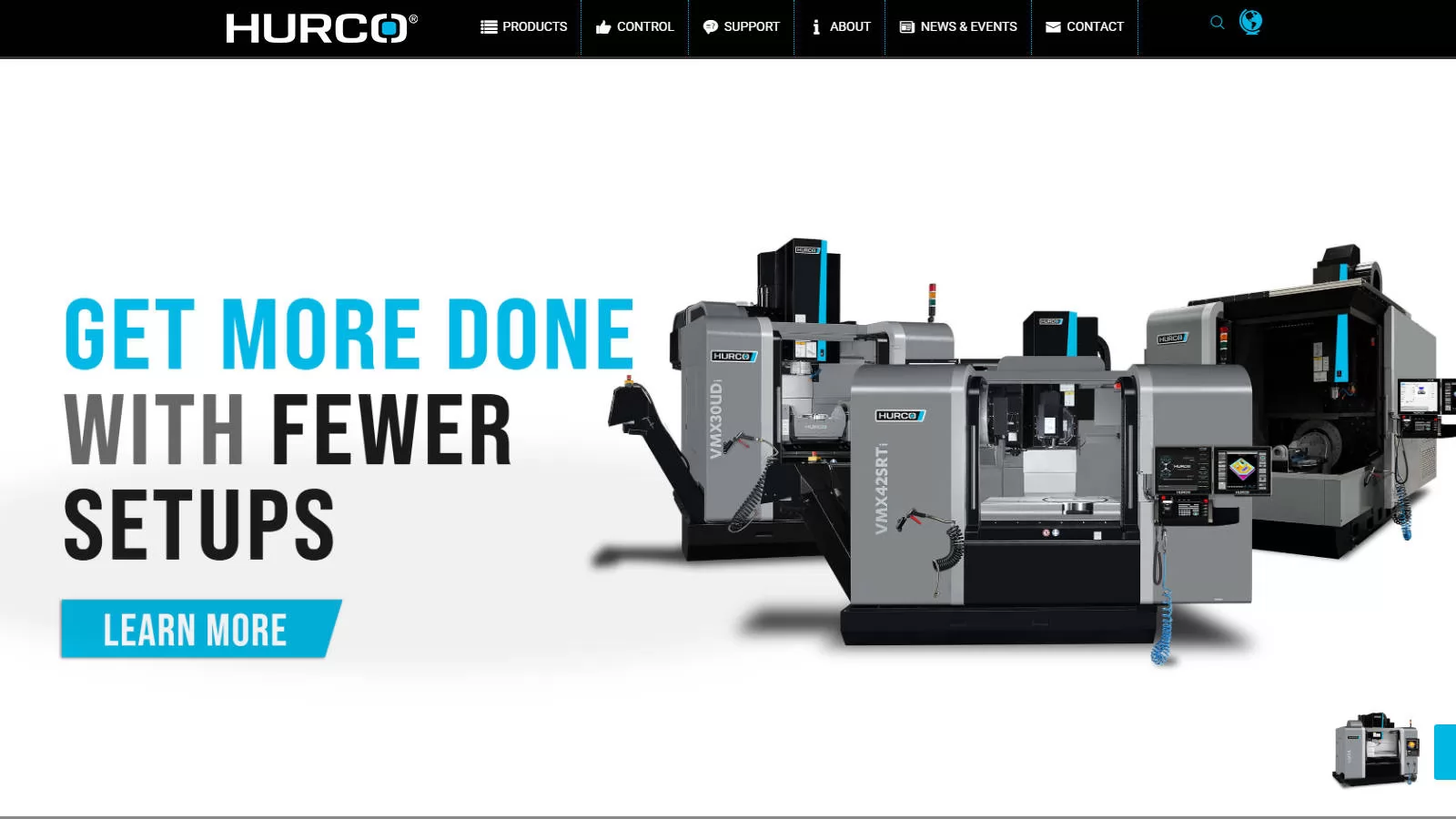

Hurco Companies

Hurco Companies

Hurco Companies, Inc., founded in 1968, is an American manufacturer known for its innovative control technology and versatile machining centers. Hurco's proprietary WinMax control system, with both conversational and NC programming capabilities, has made them a favorite among job shops and small to medium manufacturers.

Strengths

- Industry-leading conversational programming interface

- Dual-screen control option for enhanced productivity

- Excellent versatility for mixed production environments

- Good value proposition for feature set

- Strong focus on user experience and programming efficiency

Considerations

- Smaller global service network than some larger competitors

- Less specialized in high-volume production applications

Hurco offers vertical machining centers, horizontal machining centers, 5-axis machines, and turning centers. Their machines are particularly popular among job shops, tool and die makers, and prototyping operations.

Matsuura Machinery

Matsuura Machinery

Matsuura Machinery Corporation, established in 1935 in Japan, has built a reputation for high-precision, high-reliability CNC milling machines. The company has been particularly innovative in developing advanced 5-axis machining technology and automated manufacturing systems.

Strengths

- Excellent build quality and long-term reliability

- Advanced 5-axis machining capabilities

- Pioneer in lights-out manufacturing solutions

- Innovative metal 3D printing hybrid machines

- High precision and surface finish quality

Considerations

- Premium pricing structure

- Smaller product range focused on high-end applications

Matsuura specializes in vertical machining centers, horizontal machining centers, 5-axis machining centers, and hybrid additive manufacturing machines. Their technology excels in aerospace, medical, and high-precision component manufacturing.

Hermle AG

Hermle AG

Maschinenfabrik Berthold Hermle AG, founded in 1938 in Germany, has established itself as a premium manufacturer specializing in high-precision 5-axis CNC machining centers. Known for their exceptional German engineering and build quality, Hermle machines are renowned for their long-term precision, reliability, and innovative design.

Strengths

- Superior 5-axis machining capability with exceptional precision

- Distinctive gantry-style design with modified-C frame construction

- Renowned for long-term accuracy retention and thermal stability

- Advanced automation solutions and pallet changing systems

- Excellent rigidity for heavy-duty machining operations

- Proprietary control software enhancing user experience

Considerations

- Higher price point reflecting premium positioning

- Focused product range primarily on 5-axis technology

- Lower market presence in some regions compared to larger manufacturers

Hermle's product portfolio focuses on high-performance 5-axis machining centers with various sizes and configurations. Their machines are particularly valued in industries requiring exceptional precision, such as aerospace, medical technology, precision mechanics, optics, and tool and die manufacturing. The company's commitment to innovation is evident in their advanced automation solutions, including the robot systems and large magazine extensions for extended lights-out manufacturing.

Recommand Manufacturer: Haisen Machine Tools

Haisen Machine Tools

Haisen Machine Tools has rapidly established itself as a leading CNC milling machine supplier, renowned for combining cutting-edge technology with exceptional value. With a commitment to quality, innovation, and customer satisfaction, Haisen offers a comprehensive range of CNC milling solutions suitable for various industries.

The company's milling machines are designed with a perfect balance of precision engineering and user-friendly operation, making them ideal for both small workshops and large manufacturing facilities. Haisen's commitment to continuous improvement has resulted in machines that incorporate the latest advancements in CNC technology while maintaining competitive pricing.

Strengths

- Excellent value-to-performance ratio

- Comprehensive range of machine types and sizes

- Advanced control systems with intuitive interfaces

- Robust after-sales support and technical assistance

- Rapid deployment and setup capabilities

- Integration with modern manufacturing systems

Considerations

- Newer brand compared to some legacy manufacturers

- Growing global service network

Haisen's product line includes versatile vertical machining centers, high-performance horizontal machining centers, and advanced multi-axis milling solutions. Their machines are particularly noted for their thermal stability, vibration dampening properties, and precision control systems.

Learn more about Haisen's innovative CNC milling solutions at www.hs-machinetools.com.

Comparison of Top Suppliers

This comparative analysis highlights the key differences between the top CNC milling machine suppliers to help you identify which might best meet your specific manufacturing needs:

| Supplier | Price Range | Specialty | Best For | Global Presence |

|---|---|---|---|---|

| DMG MORI | Premium | High-tech, integrated solutions | High-precision industries requiring cutting-edge technology | Extensive |

| Haas Automation | Economic-Medium | User-friendly, standardized machines | Job shops, educational institutions, entry-level CNC users | Extensive |

| Makino | Premium | High-speed, high-precision milling | Die/mold, aerospace, medical industries | Strong |

| Okuma | Premium | Thermal stability, integrated systems | Industries requiring long-term stability and accuracy | Strong |

| Mazak | Medium-Premium | Multi-tasking, hybrid manufacturing | Complex part production, versatile manufacturing | Extensive |

| Doosan | Medium | Robust, reliable machines | General manufacturing, automotive supply chain | Growing |

| GROB | Premium | 5-axis, horizontal machining | Automotive, aerospace, complex part production | Moderate |

| Hurco | Medium | User-friendly controls, programming | Job shops, small batch production | Moderate |

| Matsuura | Premium | 5-axis, automation, hybrid manufacturing | High-precision components, lights-out manufacturing | Moderate |

| Hermle AG | Premium | High-precision 5-axis machining | Aerospace, medical technology, precision mechanics | Strong in Europe, Growing globally |

How to Choose the Right CNC Milling Machine Supplier

Selecting the optimal CNC milling machine supplier requires careful consideration of several factors specific to your manufacturing operation. Here's a comprehensive approach to making this critical decision:

Assess Your Manufacturing Requirements

Begin by thoroughly analyzing your specific production needs, including:

- Part complexity and required precision

- Material types to be machined

- Typical batch sizes and production volumes

- Available floor space and infrastructure

- Current and future automation needs

- Operator skill levels and training capabilities

Evaluate Total Cost of Ownership

Look beyond the initial purchase price to consider:

- Energy efficiency and consumption

- Maintenance requirements and costs

- Tooling compatibility and costs

- Operator training requirements

- Expected machine lifespan and depreciation

- Resale value potential

Investigate Support Infrastructure

A supplier's support network is crucial for minimizing downtime and maximizing productivity:

- Local service technician availability

- Spare parts availability and delivery times

- Technical support responsiveness and quality

- Application engineering assistance

- Remote diagnostic capabilities

- Warranty terms and coverage

Test Machine Capabilities

Whenever possible, evaluate actual machine performance:

- Request demonstration cuts on materials similar to your production

- Analyze surface finish quality and dimensional accuracy

- Evaluate machine stability and vibration during operation

- Test programming and setup procedures

- Measure cycle times for representative parts

Seek Industry References

Gather feedback from existing users:

- Connect with current users in similar industries

- Visit facilities using the machines you're considering

- Research online reviews and testimonials

- Consult industry forums and professional networks

- Check supplier reputation and financial stability

Future Trends in CNC Milling Technology

The CNC milling machine industry continues to evolve rapidly, with several emerging trends reshaping manufacturing capabilities. Understanding these developments can help you select a supplier whose technology roadmap aligns with future manufacturing requirements:

Automation and Robotics Integration

Automated material handling, robotic loading/unloading, and cell-based manufacturing systems are becoming increasingly accessible. Leading suppliers are developing more comprehensive automation solutions to address labor challenges and enable 24/7 production capabilities.

Artificial Intelligence and Machine Learning

Advanced algorithms are enhancing machining processes through:

- Predictive maintenance to prevent unplanned downtime

- Adaptive control systems that optimize cutting parameters in real-time

- Tool wear monitoring and automatic compensation

- Process optimization based on historical performance data

- Quality assurance through in-process monitoring

Hybrid Manufacturing

The integration of additive manufacturing (3D printing) with traditional CNC milling creates new possibilities for complex component production. Several leading suppliers now offer hybrid machines that combine metal deposition with precision machining in a single platform.

Sustainability Focus

Environmental considerations are driving innovations in:

- Energy-efficient machine designs with reduced power consumption

- Minimal quantity lubrication (MQL) and dry machining technologies

- Coolant recycling and filtration systems

- Reduced waste through optimized tool paths and material utilization

- Smaller machine footprints for reduced factory space requirements

Digital Twins and Simulation

Virtual replication of physical machines and processes enables:

- Offline programming and process verification

- Collision detection and avoidance

- Cycle time optimization before actual production

- Training in virtual environments

- Predictive analysis for process improvements

Conclusion

Selecting the right CNC milling machine supplier is a critical decision that impacts manufacturing capability, productivity, and competitiveness. Each of the top 10 suppliers reviewed in this article offers distinct advantages, specializations, and value propositions to meet different manufacturing requirements.

While established manufacturers like DMG MORI, Haas, and Makino continue to set industry standards with their technological innovations and comprehensive support networks, emerging suppliers like Haisen Machine Tools are rapidly gaining recognition by delivering excellent value, performance, and customer support.

The ideal CNC milling machine supplier for your operation depends on your specific manufacturing needs, budget constraints, technical requirements, and long-term business strategy. By carefully evaluating machine capabilities, support infrastructure, total cost of ownership, and supplier reputation, you can make an informed decision that enhances your manufacturing capabilities and drives business growth.

As CNC milling technology continues to evolve with advancements in automation, artificial intelligence, and hybrid manufacturing, partnering with a forward-thinking supplier that embraces these innovations will position your manufacturing operation for sustained success in an increasingly competitive global market.

Discover Haisen's Advanced CNC Milling Solutions

At Haisen Machine Tools, we combine cutting-edge technology with exceptional value to deliver CNC milling solutions that enhance precision, productivity, and profitability for manufacturers worldwide.

Our comprehensive product lineup includes vertical machining centers, horizontal machining centers, and multi-axis milling solutions engineered to meet diverse manufacturing requirements across industries.

From expert application support to responsive technical service, we're committed to your manufacturing success at every step.

Explore Haisen CNC Milling Machines