Explore How Structure Impacts Precision, Efficiency, and Industrial Adaptability

Contents We'll Cover

- The Engineering Behind Slant Bed and Flatbed Designs

- Performance Trade-offs: Speed, Rigidity & Precision

- Which CNC Lathe Is Better for Your Industry?

- Choosing the Right Bed Type: Key Decision Factors

- Why Leading CNC Experts Like Haisen Offer Both Options

Slant vs. Flat: It All Starts with the Bed Angle

While both machines share the same purpose — automating turning operations — the fundamental difference lies in the angle of the bed.

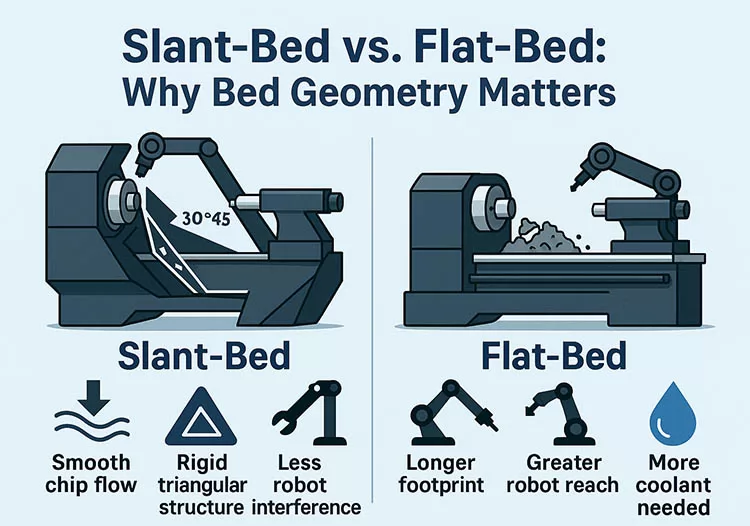

- Slant Bed CNC Lathes typically feature a bed inclined at 30°–45°, with the turret and spindle aligned to match the sloped plane.

- Flatbed CNC Lathes have a horizontally flat bed surface where the carriage and tailstock move along a straight line.

This difference may seem subtle, but it directly affects machine rigidity, chip flow, operator ergonomics, and even long-term production consistency.

Slant Bed Machines: Built for Speed and Precision

Slant bed CNC lathes shine in environments that demand fast cycle times and high repeatability. Here's why:

- Superior Chip Evacuation: Chips slide downward via gravity, minimizing heat buildup and tool wear.

- Enhanced Rigidity: The inclined design supports the tool turret closer to the workpiece, reducing deflection.

- Compact Footprint: Space-efficient layouts make them ideal for high-volume automated lines.

- Automation Ready: Better suited for robotic loading/unloading setups.

Haisen's high-speed slant bed CNC lathes are widely adopted in the precision mold and automotive parts industry, where tolerance matters down to microns.

Flatbed Machines: Durable, Adaptable, and Cost-Effective

Flatbed CNC lathes continue to be relevant in industries where large, heavy, or irregular parts are involved:

- Higher Load Capacity: Ideal for long shafts or oversized components common in energy or oil & gas industries.

- Simpler Maintenance: Straight bedways are easier to inspect and re-align over time.

- Lower Initial Investment: Fewer moving parts mean lower upfront costs, especially for conventional production.

- Operator-Friendly Layout: Better suited for manual intervention or semi-automated workflows.

Haisen's flatbed models are highly favored in overseas markets like Russia and South America for threading and heavy-duty turning operations.

Use Case Matrix: Which One Suits Your Operation?

| Feature / Application | Slant Bed CNC Lathe | Flatbed CNC Lathe |

|---|---|---|

| Best for | High-precision mass production | Heavy-duty or long-part machining |

| Chip Removal | Gravity-assisted, efficient | Manual or assisted clearing |

| Automation Compatibility | Excellent | Moderate |

| Price | Higher upfront, lower lifecycle | Lower upfront, moderate lifecycle |

| Maintenance | More complex due to incline | Simpler and direct |

How to Choose: 4 Decision Factors That Matter Most

- Production Volume: High-volume manufacturing? Go slant. Occasional or low-volume? Flatbed may suffice.

- Part Size & Shape: Flatbeds handle longer or bulkier parts better.

- Precision Requirements: For tighter tolerances and shorter cycles, slant beds have the edge.

- Budget & Space Constraints: Flatbeds are cost-effective; slant beds save space.

Why Haisen Offers Both: Tailored CNC Solutions for Every Industry

As a leading manufacturer of CNC lathe machines in China, Haisen designs both slant bed and flatbed solutions to address the nuanced needs of various industries — from automotive and hydraulic systems to precision mold and energy production.

- In-house R&D team for custom modifications

- Global service network across Europe, South America, and Southeast Asia

- CE, ISO9001, and SGS certified manufacturing standards

- 260,000㎡ production base ensuring fast delivery and quality assurance

Whether you're scaling production or customizing your workflow, Haisen helps you choose — and build — the machine that fits.

Final Thoughts: Structure Shapes Performance

When comparing slant bed and flatbed CNC lathes, the right choice hinges on what you're making, how fast you need to make it, and how precise it must be. Both designs serve vital roles in modern manufacturing, and understanding their differences ensures you invest wisely.

Looking to upgrade or expand your CNC machining capabilities?

Let Haisen's expert team help you make the right choice with tailored automation solutions and high-performance equipment.