Introduction

In the world of advanced machining, vertical lathes play a vital role in industries such as automotive, aerospace, energy, and heavy equipment manufacturing. Their ability to handle large, heavy, and complex workpieces with precision makes them indispensable for companies that require high productivity and accuracy.

As technology evolves, global competition among vertical lathe manufacturers is accelerating—driven by smart controls, automation, and digital integration. In 2025, selecting the right supplier is not only about the machine itself, but also about securing a partner for process optimization, lifecycle support, and scalable growth.

This guide profiles the Top 10 Vertical Lathe Manufacturers in the World, outlining company background, product scope, and key differentiators. At the end, we also present a recommended option—Haisen CNC Machine Tools—for buyers seeking precision, reliability, and value.

Table of Contents

- Pietro Carnaghi

- Okuma

- Soraluce

- Falcon Group Co., Ltd

- Shandong Luzhong Machine Tool Co., Ltd

- KAAST Machine Tools

- Fair Friend Group

- WMTCNC Industrial Co., Ltd

- PHILLIPS Machine Tools India

- BORUI CNC

- Recommended: Haisen CNC Machine Tools

- Conclusion

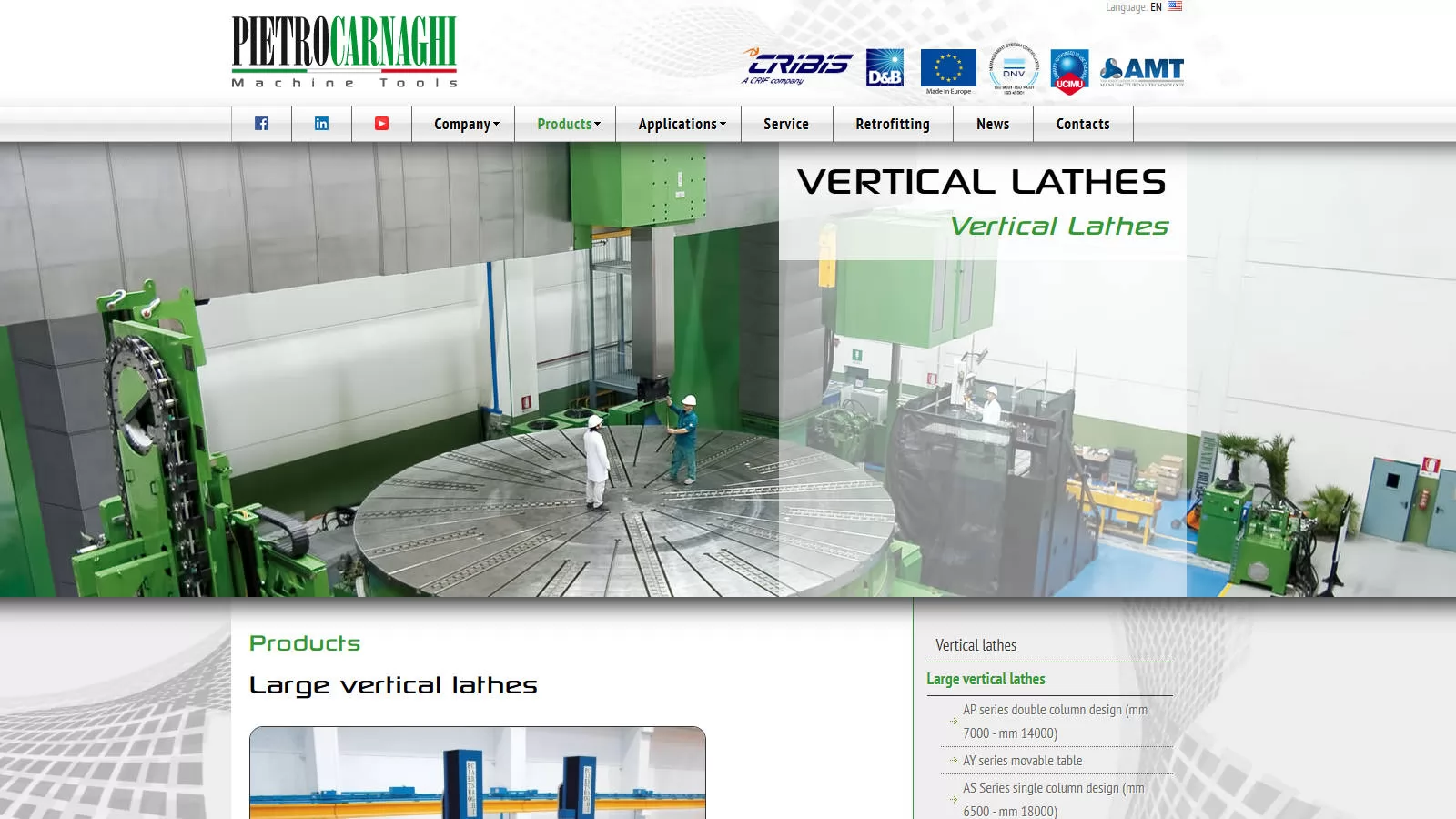

Pietro Carnaghi

Company Profile

Founded in 1922, Pietro Carnaghi has grown into one of the most respected names in the global machine tool industry, building on more than eight decades of accumulated experience and technological innovation. Still operated under the vision of the founding Carnaghi family—now in its third and fourth generations—the company combines strong traditions with forward-looking management strategies. Its culture is defined by customer orientation, innovation, and an agile organizational structure that adapts quickly to market needs. In 2009, the firm expanded its modern production facility in Villa Cortese, Milan, adding a specialized unit for large machines with a 20-meter height capacity, increasing total covered space to more than 35,000 square meters. Pietro Carnaghi is certified to UNI EN ISO 9001:2000 and ISO 45001 for workplace safety, and it integrates sustainability practices aligned with ISO 26001 guidelines. With the ability to produce approximately 40 highly engineered machines annually and thousands of installations worldwide, the company remains a benchmark for vertical lathes and advanced machining solutions.

Product

- Vertical Lathes

- Gantry Milling Machine

- Pallet Systems

- Vertical Machining Centers of Milling and Turning

Why Choose the Manufacturer

Pietro Carnaghi is a globally recognized leader in large vertical lathes, milling machines, and machining centers. Customers choose Pietro Carnaghi for its unmatched expertise in heavy-duty precision machining, serving industries such as aerospace, energy, and transportation. With decades of innovation, the company delivers highly customized solutions tailored to complex production needs. Its machines are engineered for accuracy, durability, and efficiency, making them a reliable choice for manufacturers who prioritize long-term investment and technological leadership.

Why the Manufacturer Stands Out

What sets Pietro Carnaghi apart is its strong commitment to engineering excellence and customer-focused innovation. The company’s advanced automation capabilities and integration of Industry 4.0 solutions position it as a pioneer in smart manufacturing. Pietro Carnaghi also emphasizes sustainability, designing machines that optimize energy use and minimize waste. Its strong after-sales service and global support network further enhance customer confidence, ensuring smooth operation and long-lasting performance. These combined factors distinguish the brand as one of the premier names in high-end machine tool manufacturing.

Okuma

Company Profile

Okuma is recognized worldwide as a pioneer in CNC machine tool innovation, with a history that blends technological excellence with a strong focus on customer relationships. The company’s philosophy extends far beyond building machines; it is about creating lasting partnerships with customers and supporting them throughout their manufacturing journey. Whether it is a small shop investing in its first Okuma or a global manufacturer adding to its fleet, each customer receives the same dedication to quality, precision, and service. Every machine is backed by a comprehensive warranty and supported by one of the industry’s most extensive distribution networks across the Americas and beyond. Okuma emphasizes durability, with equipment designed to perform reliably over decades of use, while also focusing on digital integration and advanced control systems that maximize productivity. This combination of innovation, customer-centric service, and global reach has made Okuma not only a leader in machine tools but also a trusted partner for long-term manufacturing success.

Product

- Vertical Lathes

- Multitasking

- Machining Centers

- Double Columns

Why Choose the Manufacturer

Okuma is a trusted Japanese manufacturer known for its wide range of CNC machine tools, including lathes, machining centers, and grinders. Customers choose Okuma because of its proven reliability, cutting-edge control systems, and advanced automation technologies. The company’s OSP control system is a key differentiator, allowing seamless integration and user-friendly operation. Industries such as automotive, aerospace, and electronics rely on Okuma’s equipment for high precision and productivity. Its long history and reputation for delivering stable, high-quality machines make it a dependable partner for global manufacturers.

Why the Manufacturer Stands Out

Okuma stands out due to its innovative approach to machine tool design and automation. Its unique “Thermo-Friendly Concept” ensures consistent machining accuracy under varying environmental conditions. The integration of intelligent monitoring and predictive maintenance systems enhances efficiency while reducing downtime. Okuma’s focus on continuous R&D and customer training ensures clients stay ahead in competitive markets. By combining tradition with technological advancement, Okuma has built a strong global brand identity as a reliable and forward-looking machine tool manufacturer.

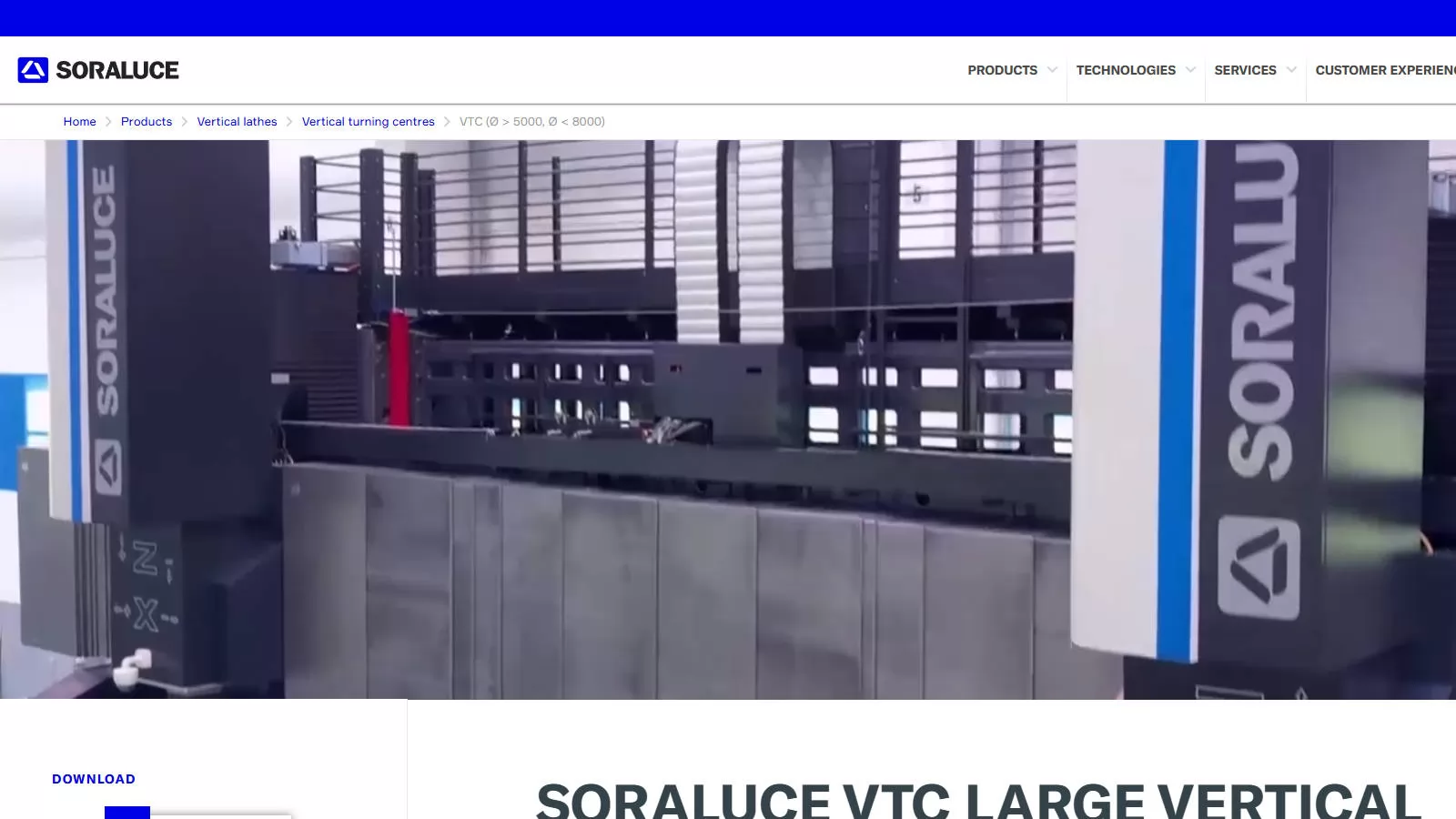

Soraluce

Company Profile

Soraluce has earned a reputation for delivering reliable, high-performance machine tools built on a foundation of technological excellence, innovation, and customer service. Known for its advanced vertical turning, milling, and boring machines, the company consistently develops new solutions to tackle the most demanding machining challenges. Soraluce offers a wide portfolio of multitasking machines, automated systems, and precision engineering services, all designed to optimize customers’ production efficiency. Its engineering team works closely with clients, analyzing manufacturing processes and providing tailored solutions to enhance productivity and accuracy. Distinguished by a strong international outlook, Soraluce serves clients across multiple continents, continually setting new benchmarks in machining standards. The company’s ability to combine advanced R&D, practical expertise, and customer-focused engineering makes it a leader in vertical lathe and milling technology, trusted by industries that demand performance, innovation, and long-term reliability in their production systems.

Product

- Milling Machines

- Multitasking Machines

- Vertical Lathes

- Fast Delivery Machines

Why Choose the Manufacturer

Soraluce, part of the Danobatgroup, is a leader in milling, boring, and multi-tasking machines. Customers choose Soraluce for its innovative solutions in machining large and complex components across industries such as energy, shipbuilding, and industrial equipment. The company’s machines are designed for stability, versatility, and accuracy, ensuring exceptional productivity. Soraluce places a strong emphasis on user-centric design, providing ergonomic, efficient, and safe solutions. Its continuous focus on process optimization enables manufacturers to achieve higher efficiency and reduced costs, making Soraluce a preferred choice worldwide.

Why the Manufacturer Stands Out

Soraluce stands out for its groundbreaking technological developments, including dynamic damping systems and adaptive control solutions. These innovations reduce vibration, increase precision, and extend tool life, setting new standards in machine tool performance. The company also distinguishes itself with its service-oriented approach, offering lifecycle support and customized training programs. Soraluce’s strong reputation for solving complex machining challenges and delivering tailored solutions enhances its global recognition. With a culture of innovation and close collaboration with clients, Soraluce positions itself as a trusted industry innovator.

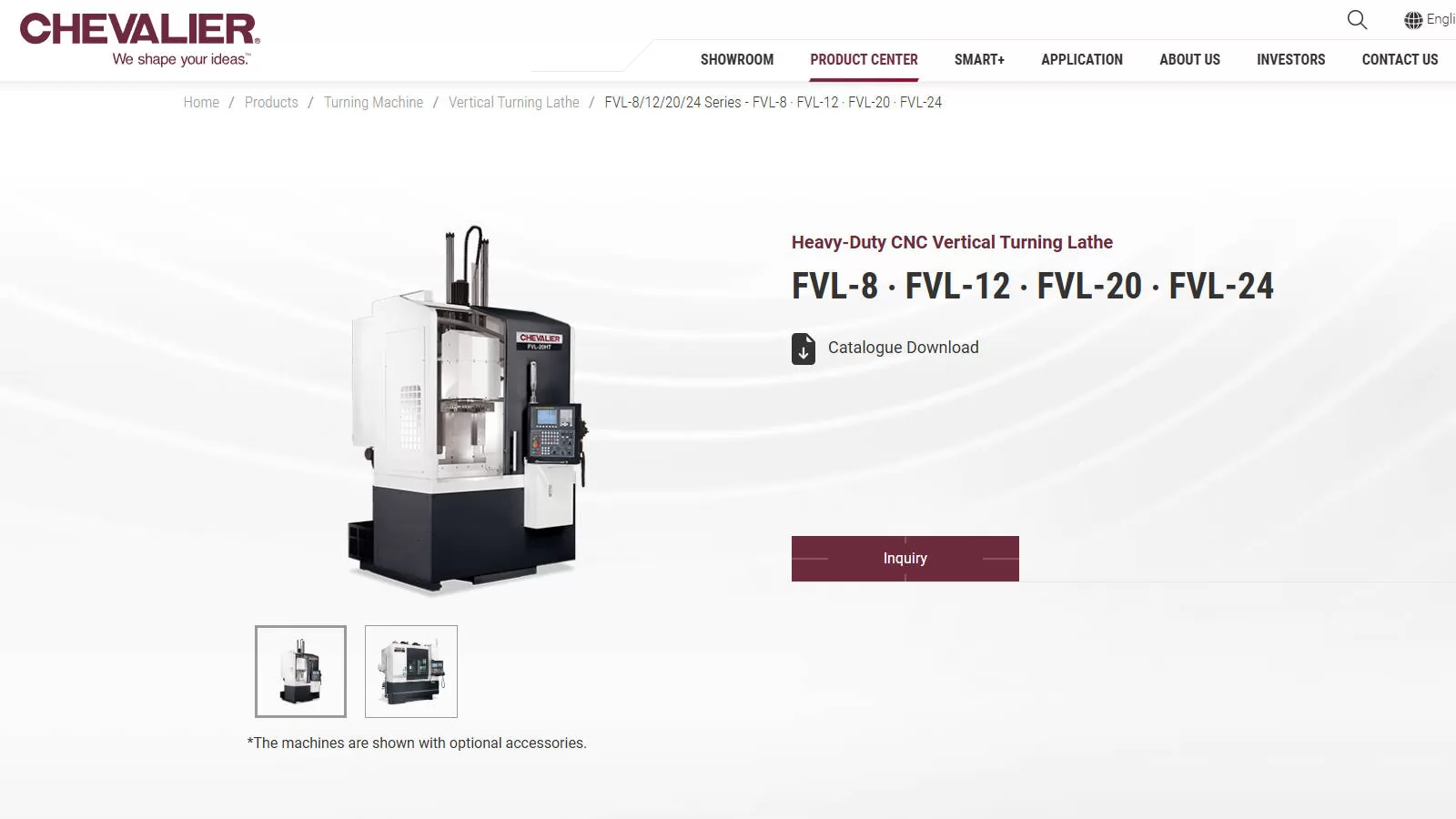

Falcon Group Co., Ltd

Company Profile

Established in 1978, Falcon Group Co., Ltd. is a prominent Taiwanese manufacturer with a diversified product line that includes grinding machines, milling machines, and lathes. Operating under its well-known proprietary brand “CHEVALIER,” the company has built a strong presence in both domestic and international markets. Falcon Group has subsidiaries in the United States and mainland China, and its extensive distributor network spans more than 80 countries worldwide, covering Europe, South America, the Middle East, and Asia. Guided by the leadership of Chairman Mr. Lin Tsung Lin and General Manager Mr. Alan Tung since 2022, the company has reinforced its commitment to quality and innovation. Its corporate philosophy centers on human-centric design and precision manufacturing, values that are applied not only in machine tool development but also in its expansion into construction-related industries. With a diversified growth strategy and strong customer support, Falcon Group continues to push boundaries, positioning itself as a global leader in advanced machine tools.

Product

- Grinding Machine

- Fully Automatic Precision Surface Grinder (iSurface control)

- Vertical Grinding Center

- CNC Rotary Surface Grinder

- Milling Machine, Machining Center

Why Choose the Manufacturer

Falcon Group Co., Ltd, also known as Chevalier, is a prominent machine tool manufacturer specializing in grinding, turning, and milling solutions. Customers choose Falcon for its ability to combine precision engineering with robust production capabilities. The company’s wide product range serves industries from automotive to medical devices, ensuring versatility and adaptability. With decades of experience and global presence, Falcon Group has earned customer trust for reliable performance and consistent product quality. Its focus on R&D ensures cutting-edge solutions that align with evolving manufacturing needs.

Why the Manufacturer Stands Out

Falcon Group stands out through its strong emphasis on innovation and international expansion. Its machines integrate advanced CNC technology with user-friendly interfaces, improving operational efficiency. Falcon also differentiates itself by offering comprehensive customer support, including training and technical assistance worldwide. The company’s commitment to quality assurance and rigorous testing processes ensures each machine meets high global standards. By maintaining a balance between affordability and performance, Falcon has built a reputation as a competitive, innovative, and customer-focused manufacturer in the global machine tool industry.

Shandong Luzhong Machine Tool Co., Ltd

Company Profile

Shandong Luzhong Machine Tool Co., Ltd. is a large-scale Chinese manufacturer with over three decades of expertise in CNC machine tool production. Covering 100,000 square meters of factory space, the company operates with more than 100 advanced machining systems and 50 precision testing devices, ensuring rigorous quality standards at every stage of manufacturing. With a workforce of over 200 employees—including 30 senior engineers and more than 100 highly skilled technicians—the company has built a strong technical foundation for continuous innovation and intelligent manufacturing. Its product portfolio spans CNC vertical and horizontal machining centers, gantry machining centers, flat and slant bed CNC lathes, and vertical lathes, with annual production capacity exceeding 2,500 units across more than 100 models. Luzhong machines are widely applied in aerospace, defense, automotive, energy, and shipbuilding sectors, and the company holds multiple patents and international certifications including ISO, CE, TUV, BV, SGS, and EAC. Exported to more than 150 countries, Luzhong is committed to long-term partnerships, professional overseas support, and advancing China’s presence in the global machine tool market.

Product

- Vertical Machining Center

- Horizontal Machining Center

- Gantry Machining Center

- 5 Axis CNC Machining Center

- CNC Vertical Lathe Machine

Why Choose the Manufacturer

Shandong Luzhong Machine Tool Co., Ltd is a leading Chinese manufacturer offering a wide variety of CNC lathes, milling machines, and machining centers. Customers choose Luzhong for its cost-effective solutions, broad product range, and adaptability to diverse industry needs. The company is known for balancing affordability with quality, making advanced machining technologies more accessible to small and medium-sized enterprises. Its strong production capabilities and continuous improvements in automation attract global clients seeking efficient and practical manufacturing solutions.

Why the Manufacturer Stands Out

Shandong Luzhong stands out for its ability to provide high-performance machines at competitive prices without compromising on reliability. The company emphasizes customization, enabling clients to tailor machines to their exact requirements. Its focus on building long-term relationships through excellent service and technical support strengthens customer trust. Luzhong also invests in modern manufacturing facilities and quality control systems, ensuring international standards compliance. By combining affordability, customization, and dependable performance, Luzhong has positioned itself as a fast-growing and competitive brand in the global machine tool market.

KAAST Machine Tools

Company Profile

Founded in Germany in 2009 and expanded into the United States in 2010, KAAST Machine Tools has quickly established a global reputation for delivering high-performance and durable machinery. The company’s product range is broad, covering precision lathes, mills, grinders, band saws, presses, and plate rollers. Chip-making machines are manufactured in Taiwan, while fabrication equipment is produced in Turkey, ensuring a balance of engineering quality and cost efficiency. Designed to withstand demanding production environments, KAAST machines provide exceptional accuracy, productivity, and longevity with minimal maintenance requirements. Serving industries such as aerospace, automotive, defense, energy, and construction, KAAST offers versatile solutions tailored to each customer’s needs. Its state-of-the-art showroom allows clients to see machines in action, reinforcing transparency and trust in product performance. With installations across the globe and a customer-focused philosophy, KAAST continues to be a strong partner for companies seeking reliable, efficient, and innovative manufacturing tools.

Product

- CNC - Slant Bed

- CNC - Teach Style

- CNC - VTL

- Manual - Engine Lathes

- Manual - Large Swing Lathes

- Manual - Vertical Lathes

Why Choose the Manufacturer

KAAST Machine Tools has built a reputation for delivering a broad range of CNC and manual machines designed for precision and versatility. Customers choose KAAST for its ability to provide both standardized and customized solutions across industries, from prototyping to mass production. The company emphasizes ease of use, training, and long-term support, ensuring that users maximize efficiency and ROI. By combining German engineering standards with global manufacturing, KAAST guarantees consistent quality, durability, and advanced technology at competitive pricing, making it a reliable partner for businesses seeking comprehensive machine tool solutions.

Why the Manufacturer Stands Out

What distinguishes KAAST is its global presence and commitment to customer-centric service. Unlike many machine tool providers, KAAST maintains a diverse product portfolio that covers lathes, mills, presses, and plasma cutting equipment. Its ability to integrate traditional craftsmanship with modern CNC innovation appeals to companies looking for scalable solutions. Additionally, KAAST places strong emphasis on operator training and after-sales care, giving customers confidence in long-term performance. With a proven record of delivering tailored machines for different markets, KAAST stands out as a trusted source for high-quality, user-friendly equipment designed to meet evolving industrial demands.

Fair Friend Group

Company Profile

Fair Friend Group’s Machine Tool Division, established in 1985, has grown from manufacturing sawing and grinding machines to becoming one of the largest machine tool groups in the world. Recognizing early the importance of automation and CNC technology, FFG launched its FEELER brand the same year, gaining strong traction in overseas markets. In 1986, the company built Taiwan’s first moving column vertical machining center, which was widely acclaimed and marked the beginning of its CNC success. Over time, FFG expanded its product line to include CNC lathes and many other advanced machines, ultimately creating a complete manufacturing ecosystem. Today, FFG oversees 37 machine tool brands and 50 production bases across 10 major manufacturing countries, including Taiwan, the United States, China, Germany, Japan, and Italy. This scale positions FFG as the largest vertical machinery manufacturing group worldwide, offering customers advanced technology, global support, and an unmatched range of machine tool solutions.

Product

- Vertical CNC Lathes

- Horizontal CNC Lathes

- Vertical Machining Center

- Horizontal Machining Center

- 5-Axis Vertical Machining Center

Why Choose the Manufacturer

Fair Friend Group (FFG) is one of the world’s largest machine tool conglomerates, offering unmatched variety and production capacity. Customers benefit from FFG’s global network of brands, which enables access to specialized solutions for automotive, aerospace, energy, and precision engineering. The group’s financial strength ensures sustainable investment in R&D and cutting-edge facilities. By choosing FFG, customers partner with a manufacturer capable of delivering not just individual machines, but entire manufacturing ecosystems. This scalability, combined with strong supply chain integration, makes FFG a reliable choice for organizations pursuing long-term growth and advanced production capabilities.

Why the Manufacturer Stands Out

FFG stands out for its sheer scale and diversity, operating more than 50 production facilities worldwide and managing a portfolio of over 30 brands. Unlike many competitors, FFG integrates multiple technologies under one umbrella, allowing clients to access everything from vertical machining centers to high-precision grinders. Its leadership in innovation and global distribution capacity sets it apart, enabling fast delivery and consistent support across continents. FFG’s strength lies not only in manufacturing capacity but also in its ability to respond quickly to industry shifts, making it a dominant and forward-thinking force in the global machine tool market.

WMTCNC Industrial Co., Ltd

Company Profile

WMTCNC Industrial Co., Ltd. is a leading international manufacturer and solution provider, offering an extensive range of machine tools and manufacturing equipment. The company integrates research and development, production, sales, and after-sales service, delivering end-to-end solutions to clients worldwide. With a strong focus on technological innovation, WMTCNC products are engineered for precision, efficiency, and reliability. Currently, the company exports to more than 150 countries and regions, serving key sectors such as aerospace, automotive, electronics, and precision engineering. WMTCNC’s equipment is trusted for its long service life, stable performance, and adaptability to modern manufacturing demands. Beyond hardware, the company emphasizes professional customer support and technical consultation, helping clients enhance productivity and competitiveness. As WMTCNC expands its global presence, it continues to invest in digital manufacturing and automation solutions, reinforcing its role as a reliable partner for industries that demand cutting-edge machine tools and consistent quality worldwide.

Product

- Cnc Vertical Lathe

- Cnc Milling

- Cnc Drilling Tapping Center

- Milling Boring Machine

- Grinding Machine

- Automobile Maintenance & Repair

Why Choose the Manufacturer

WMTCNC Industrial is recognized for offering high-value CNC machines tailored to small and medium enterprises. Customers choose WMTCNC for its focus on affordability without compromising precision or durability. The company’s product line includes CNC lathes, milling machines, and machining centers, designed for workshops requiring versatile and efficient solutions. WMTCNC also emphasizes user-friendly design, making its machines accessible for operators with varying skill levels. Its combination of technical reliability, competitive pricing, and responsive customer support makes WMTCNC an appealing choice for businesses looking to balance cost-effectiveness with manufacturing performance.

Why the Manufacturer Stands Out

WMTCNC stands out through its strategic focus on SMEs, positioning itself as a go-to supplier for companies seeking entry-level or mid-range CNC solutions. Unlike larger competitors, WMTCNC adapts quickly to client needs by offering compact, space-saving designs that deliver industrial-grade performance. The company’s dedication to continuous product refinement ensures that even budget-conscious customers gain access to modern CNC technology. Its strong after-sales support and training services add value beyond the initial purchase. By combining affordability, adaptability, and reliability, WMTCNC has carved out a distinctive position in the machine tool industry.

PHILLIPS Machine Tools India

Company Profile

Phillips Machine Tools India is one of the nation’s largest distributors of advanced manufacturing equipment, representing world-class brands and technologies. Beyond supplying machines, Phillips has built its reputation on offering complete solutions that empower manufacturers to achieve higher productivity and efficiency. The company’s “Phillips 360 Team” approach provides customers with access to expert guidance, rapid service, training, and tailored solutions designed to maximize equipment performance. By focusing on both machines and people, Phillips ensures that every client receives not only cutting-edge technology but also long-term support for sustained success. Its portfolio serves a wide range of industries, from aerospace and defense to automotive and general engineering, positioning Phillips as a trusted partner in India’s growing manufacturing sector. With its customer-first philosophy and commitment to innovation, Phillips Machine Tools continues to play a vital role in shaping the future of Indian manufacturing.

Product

- Milling Machines

- Vertical Turning Machines

- Grinding Machines

Why Choose the Manufacturer

PHILLIPS Machine Tools India has been a trusted partner for manufacturers across India, offering global machine brands with localized support. Customers choose PHILLIPS for its strong technical expertise, training programs, and ability to integrate world-class technology into local industries. As an authorized distributor for leading machine tool brands, PHILLIPS ensures customers receive both international standards and regional service reliability. Its broad product portfolio supports industries ranging from automotive to aerospace, making it an essential choice for Indian companies seeking modern, high-performance machines with reliable after-sales care.

Why the Manufacturer Stands Out

What makes PHILLIPS stand out is its dual role as both a distributor of globally renowned machine tool brands and a local solutions provider. Unlike many regional suppliers, PHILLIPS combines international quality with deep understanding of the Indian manufacturing ecosystem. Its extensive training centers, service teams, and application engineering expertise ensure that customers gain more than just machines—they gain a complete productivity solution. By bridging the gap between global innovation and local application, PHILLIPS stands out as a market leader that enhances India’s industrial capabilities and technological competitiveness.

BORUI CNC

Company Profile

Founded in 2015 in Tengzhou City’s Economic Development Zone, BORUI CNC is a fast-growing high-tech enterprise dedicated to the design, production, and service of advanced CNC machine tools. Its product range includes vertical and horizontal machining centers, CNC milling machines, lathes, and band saw machines, supported by in-house casting quality and self-operated import and export rights. Despite being a relatively young company, BORUI has quickly earned recognition for its focus on quality, innovation, and customer satisfaction. Its machines are applied across a wide spectrum of industries, from automotive to heavy engineering, where precision and reliability are critical. BORUI combines strict quality control with professional after-sales service to ensure long-term customer trust. With an ambition to become one of the world’s most reliable CNC manufacturers, the company continues to invest in research, technology, and global expansion, bringing efficient and affordable machining solutions to customers worldwide.

Product

- Vertical Machining Center

- Vertical Milling Machine

- CNC Pipe Threading Lathe Machine

- CNC Vertical Lathe Machine

Why Choose the Manufacturer

BORUI CNC is a rising manufacturer specializing in CNC machines that blend cost-effectiveness with reliability. Customers choose BORUI for its strong engineering foundation and dedication to precision manufacturing. The company focuses on providing CNC lathes, milling machines, and machining centers that meet the needs of both domestic and international markets. Its competitive pricing and quality assurance processes ensure that customers get machines capable of consistent performance at a fraction of the cost of premium global brands. BORUI appeals to businesses seeking an emerging partner with strong growth potential and technical dedication.

Why the Manufacturer Stands Out

BORUI stands out by positioning itself as a dynamic, growth-oriented company with global ambitions. Unlike older manufacturers with rigid systems, BORUI embraces flexibility and innovation, tailoring its CNC machines to evolving customer needs. The company emphasizes continuous R&D investment, allowing it to quickly adopt advanced machining technologies. By combining affordability with modern engineering, BORUI provides accessible solutions for manufacturers entering higher-precision markets. Its adaptability, forward-looking approach, and commitment to expanding international presence differentiate BORUI as a promising and competitive CNC manufacturer on the global stage.

Recommended: Haisen CNC Machine Tools

Company Profile

Dalian Haisen Machinery Co., Ltd. is a renowned high-tech enterprise in China specializing in high-speed, high-precision CNC machine tools. Known for continuous innovation, the company integrates R&D, production, and quality inspection to deliver advanced lathe and milling solutions. Its product portfolio spans vertical and horizontal CNC lathes, Swiss-type lathes, pipe threading machines, milling machines, gantry machining centers, and grinding equipment, serving industries such as energy, telecommunications, automotive, oil and gas, and precision mold manufacturing. Haisen’s machines are exported to markets including Russia, the UK, Turkey, South America, and Africa, where they are highly valued for their durability and accuracy. Beyond manufacturing, the company provides automation solutions and strong after-sales support, helping customers improve efficiency and competitiveness. Recognized both domestically and internationally, Haisen views growing customer trust as both an honor and a responsibility. By turning market challenges into motivation, the company remains committed to innovation, refined management, and creating greater value for clients worldwide.

Product

- Turning Lathe

- Automatic CNC Lathe

- Pipe Threading Lathe

- Vertical Turret Lathe

- Swiss Type CNC Lathe

- Machining Center

Why Choose Haisen

Haisen is a trusted Chinese manufacturer specializing in high-precision, high-speed CNC machine tools. Customers choose Haisen for its focus on quality, innovation, and export expertise. Its advanced CNC lathes and milling machines are widely used in industries such as energy, mold manufacturing, petroleum, and automotive. With international certifications and a strong presence in Europe, the Americas, and Asia, Haisen ensures compliance with global standards. By combining cutting-edge design, strict quality management, and customer-oriented service, Haisen offers reliable solutions for businesses aiming to upgrade production efficiency and achieve world-class machining results.

Why Haisen Stands Out

Haisen stands out for its blend of technological innovation and global competitiveness. Unlike many regional manufacturers, Haisen positions itself as a high-tech enterprise capable of competing with top-tier international brands. Its focus on precision, speed, and durability allows it to deliver machines suited for demanding applications. Moreover, Haisen’s commitment to customization and client collaboration makes it a flexible partner for industries with specialized requirements. With a reputation for exporting to diverse global markets and maintaining international certifications, Haisen distinguishes itself as a trusted, forward-looking CNC machine tool manufacturer driving China’s presence in advanced manufacturing.

Conclusion

Vertical lathes remain essential for heavy, precise, and repeatable machining tasks. Reviewing the top vertical lathe manufacturers clarifies today’s technology landscape—from structural rigidity and spindle performance to control systems and automation. If you need a partner that balances precision, reliability, and lifecycle value, Haisen is a strong recommendation for 2025 and beyond.