Expert advice from Haisen — understand axis systems, choose the right machine, and optimize production for high-precision, high-speed CNC machining.

Introduction

In modern precision manufacturing, choosing the right CNC axis configuration is a strategic decision that affects part quality, cycle time, and overall return on investment. This guide explains the core differences between 3-axis, 4-axis, and 5-axis CNC machining, clarifies common misconceptions, and provides practical selection criteria that manufacturing engineers and production managers can apply immediately. Throughout the article we also highlight how Haisen designs and configures high-rigidity, high-speed CNC machines to deliver stable micron-level accuracy across a wide range of industrial applications.

Table of Contents

CNC Coordinate System Explained

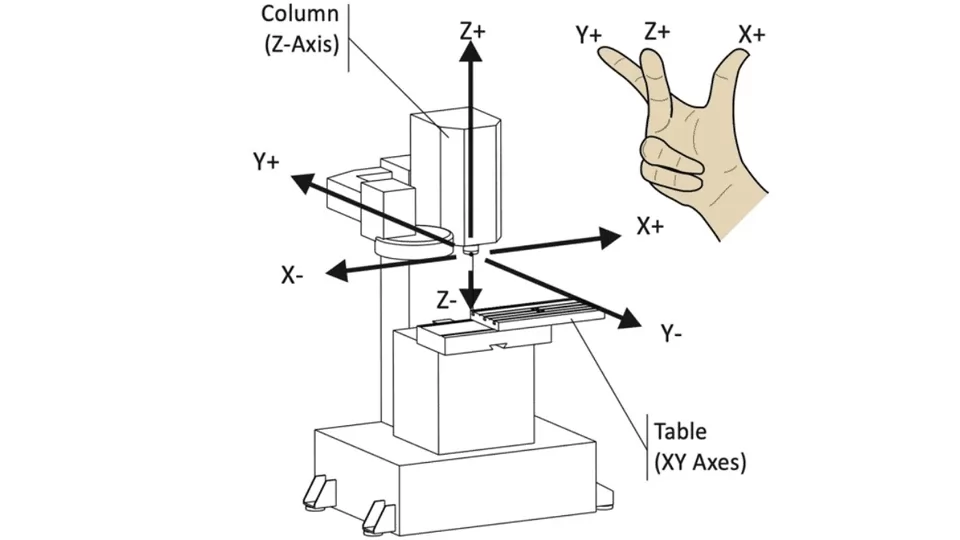

The CNC coordinate system is the foundation for programming, toolpath generation, and machine motion control. It establishes a shared frame of reference between the part geometry, the CAM output, and the machine tool so that every move is predictable and repeatable. Understanding both linear and rotational axes is essential when comparing 3-axis, 4-axis, and 5-axis CNC machines.

Linear Axes (X, Y, Z)

Linear axes define translational movement in three perpendicular directions:

- X-axis: Horizontal left-to-right travel when viewed from the operator position. Commonly used for lateral cuts and profiling.

- Y-axis: Horizontal front-to-back travel, enabling depth and contouring across the part plane.

- Z-axis: Vertical up-and-down travel, controlling tool engagement and depth of cut.

Together X, Y and Z form a Cartesian grid that CAM systems and G-code use to define every point in a toolpath. Most standard 3-axis operations rely solely on these linear axes; additional rotational axes introduce angular freedom that reduces setups and extends machinable geometry.

Rotational Axes (A, B, C)

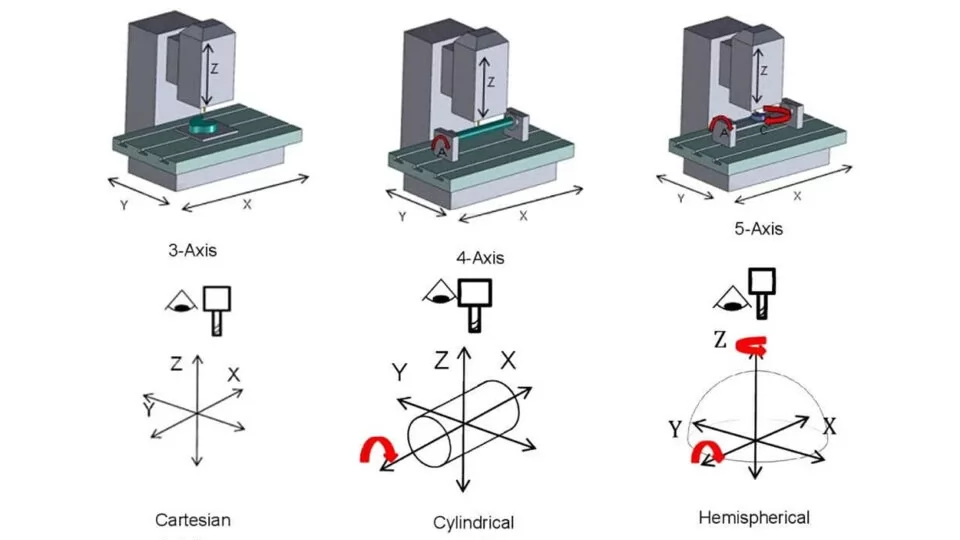

Rotational axes represent angular motion around the linear axes, extending the machining freedom from simple planar operations to complex multi-sided geometries. These rotations are typically designated as:

- A-axis: Rotation around the X-axis, allowing the workpiece to tilt forward or backward.

- B-axis: Rotation around the Y-axis, enabling the spindle head or table to pivot sideways.

- C-axis: Rotation around the Z-axis, providing full 360° part rotation, commonly used in turning centers and advanced milling machines.

When combined with X, Y, and Z, these rotational movements unlock true multi-axis machining capabilities. Instead of manually repositioning the part multiple times, the machine can automatically reorient the tool or workpiece, improving both accuracy and productivity.

Understanding how these axes interact is critical before choosing between 3-axis, 4-axis, and 5-axis CNC configurations, as each adds different degrees of motion and programming complexity.

What Is 3-Axis CNC Machining?

3-axis CNC machining is the most fundamental and widely used configuration, suitable for flat surfaces and geometries that can be accessed from a single direction. In this setup, the cutting tool moves along the X, Y, and Z axes simultaneously, while the workpiece remains fixed on the machine table.

Key Capabilities

- Precise contouring, drilling, pocketing, and milling of planar and prismatic parts.

- Excellent surface finish and dimensional repeatability for 2.5D geometries.

- Efficient for materials such as aluminum, steel, and engineering plastics.

Advantages

- Lower initial investment and simpler programming requirements.

- Shorter setup time with minimal operator training.

- Broad compatibility with standard G-code and CAM systems.

Limitations

- Requires manual repositioning of the part for features on multiple faces.

- Limited capability for undercuts and complex curved surfaces.

- Reduced efficiency for parts requiring multiple setups or angular features.

Overall, 3-axis CNC machining remains the workhorse of the manufacturing industry, ideal for medium-complexity components, prototype fabrication, and cost-sensitive production runs.

What Is 4-Axis CNC Machining?

4-axis CNC machining builds upon the 3-axis foundation by adding one rotational degree of freedom — typically the A-axis — which rotates the workpiece around the X-axis. This enables the cutting tool to access multiple sides of the part in a single setup, significantly reducing manual intervention and setup time.

Key Capabilities

- Simultaneous 4-axis interpolation for complex features such as slots, pockets, and engravings on cylindrical surfaces.

- High precision in machining multiple faces of a component without reclamping.

- Enhanced repeatability in production runs where part orientation must remain consistent.

Advantages

- Reduces setup time and operator handling by enabling automatic part rotation.

- Improves geometric accuracy for components with side features or bores.

- Ideal for machining turbine blades, cams, impellers, and flanges.

Limitations

- Programming complexity increases slightly compared with 3-axis systems.

- Still limited for fully contoured freeform surfaces requiring simultaneous multi-axis motion.

What Is 5-Axis CNC Machining?

5-axis CNC machining represents the pinnacle of modern precision manufacturing. In addition to the three linear axes (X, Y, Z), the machine includes two rotational axes — typically A and B — allowing the cutting tool to approach the workpiece from virtually any direction.

Key Capabilities

- Simultaneous multi-axis contouring for complex 3D surfaces such as molds, aerospace components, and medical implants.

- Single-setup machining of intricate geometries, minimizing repositioning errors.

- Superior surface finish through optimal tool orientation and constant contact angles.

Advantages

- Exceptional precision and repeatability, even on curved or twisted geometries.

- Reduced cycle time and tool wear due to optimized tool engagement.

- Wider material compatibility, from aluminum and titanium to Inconel and hardened steel.

Limitations

- Higher capital cost and more advanced programming requirements.

- Demands skilled operators and precise calibration for optimal results.

5-axis machines are indispensable in industries such as aerospace, medical device production, and precision tooling — where part complexity and tolerance control are non-negotiable.

Comparison Table: 3-Axis vs 4-Axis vs 5-Axis CNC Machining

| Feature | 3-Axis CNC | 4-Axis CNC | 5-Axis CNC |

|---|---|---|---|

| Number of Motion Axes | X, Y, Z | X, Y, Z + A (or C) | X, Y, Z + A + B (or C) |

| Part Accessibility | Single face per setup | Multiple faces per setup | Full multi-angle access |

| Programming Complexity | Basic (2.5D/3D) | Moderate | Advanced 3D contouring |

| Machining Speed & Efficiency | Moderate | High | Very High |

| Typical Applications | Flat parts, molds, brackets | Cylindrical components, cams, fixtures | Aerospace, medical, complex dies |

| Investment Cost | Low | Medium | High |

As seen above, each CNC configuration serves different operational goals. The ideal choice depends on part geometry, required precision, and production volume — factors that we will explore in the next section.

How to Choose the Right Axis System

Selecting between 3-axis, 4-axis, and 5-axis CNC machines requires balancing geometry complexity, production volume, and precision requirements. Each axis configuration offers unique strengths that align with specific manufacturing objectives.

1. Evaluate Part Geometry

- For simple, planar parts and 2.5D contours, a 3-axis CNC system is both cost-effective and easy to program. - When components require side holes, angular cuts, or engraving around cylinders, a 4-axis CNC machine minimizes manual repositioning. - For organic, contoured, or freeform geometries found in aerospace blades or orthopedic implants, 5-axis CNC machining ensures continuous precision and minimal tool repositioning.

2. Consider Production Volume

- In small-batch or prototype environments, 3-axis setups are sufficient. - For medium-volume production, 4-axis machining improves efficiency through fewer setups. - In high-volume or automated lines, 5-axis systems with pallet changers and probing deliver superior throughput and repeatability.

3. Balance Investment vs. ROI

A 5-axis system offers maximum flexibility but requires higher capital and skilled operation. For many workshops, upgrading from 3-axis to 4-axis provides the best balance between cost and productivity improvement.

4. Match Machine Type to Industry

- Mold and Die Manufacturing: 3-axis and 5-axis systems dominate due to complex cavity shapes.

- Aerospace and Defense: 5-axis machining is standard for turbine, impeller, and airframe components.

- Automotive: 4-axis machining efficiently produces engine housings and transmission parts.

- Energy and Oilfield: High-rigidity 4-axis and 5-axis machines handle large, heavy components with precision.

Ultimately, the right axis configuration is not about owning the most advanced machine, but about aligning capability with your design complexity, material type, and production strategy.

Why Choose Haisen CNC Machines

As a high-precision CNC machine manufacturer, Haisen has dedicated years to developing advanced turning and milling solutions that combine speed, rigidity, and reliability. Our product range covers 3-axis, 4-axis, and 5-axis CNC machining centers tailored for mold manufacturing, automotive production, energy applications, and precision engineering.

Why Choose Haisen

- Precision Engineering: High-rigidity cast-iron structures, dynamic thermal stability, and micron-level accuracy.

- High-Speed Control: Intelligent servo systems for smoother interpolation and reduced cycle times.

- Customizable Solutions: Configurable axis setups, spindle speeds, and automation options for specific industries.

- Global Support: Exported to Europe, America, and Asia with certified quality and responsive technical service.

Whether your goal is to upgrade from 3-axis to 5-axis machining, expand production capacity, or achieve tighter tolerances, Haisen provides end-to-end solutions that enhance both performance and profitability.

Contact Haisen for a Custom CNC Solution

Learn how our advanced CNC machines can optimize your workflow and reduce your machining costs. Visit Haisen’s official website or contact us to discuss your production requirements.

FAQs About 3-Axis, 4-Axis, and 5-Axis CNC Machining

1. What is the main difference between 3-axis, 4-axis, and 5-axis CNC machines?

The main difference lies in the number of movement directions. A 3-axis machine moves the tool along X, Y, and Z axes. A 4-axis adds rotation around one axis, while a 5-axis system introduces two rotational axes, allowing the tool to approach the part from virtually any angle. This provides greater flexibility, fewer setups, and higher precision for complex geometries.

2. Is a 5-axis CNC machine always better than a 3-axis or 4-axis?

Not necessarily. Although 5-axis machining offers unmatched precision and versatility, it also requires higher investment and skilled programming. For simpler parts or flat components, a 3-axis or 4-axis CNC can deliver the same accuracy at a lower cost. The right choice depends on part complexity, production volume, and your machining objectives.

3. What industries benefit most from 5-axis CNC machining?

5-axis CNC machining is widely used in aerospace, automotive, medical device, and mold manufacturing. Its ability to handle complex freeform surfaces and maintain micron-level tolerances makes it ideal for turbine blades, implants, precision molds, and high-performance engine parts.

4. How accurate is a modern CNC machining center?

Accuracy depends on machine design, spindle quality, and thermal stability. Premium CNC machining centers can achieve tolerances within ±0.002 mm or better, especially when equipped with advanced feedback systems and temperature compensation. Haisen’s precision CNC machines are engineered to maintain this level of accuracy under continuous operation.

5. Is 4-axis CNC machining worth upgrading from 3-axis?

Yes, for manufacturers producing medium-complexity parts with features on multiple faces, a 4-axis CNC provides excellent ROI. It reduces setup times, improves consistency, and enhances productivity — often without the programming challenges or cost of a 5-axis system.

6. How can I choose the best CNC machine manufacturer?

Look for a manufacturer with proven expertise in both machine design and after-sales support. Evaluate factors such as spindle configuration, rigidity, software compatibility, and customization capability. Haisen combines advanced R&D, precision assembly, and comprehensive technical service to ensure long-term reliability and productivity for every client.